About the project

The inner tube is often a technical element with a very specific use. However, it ends up pierced, damaged or worn, which takes away its maintenance function. The consumer prefers to buy a new one rather than repair it. It remains usable, but is in the trash.

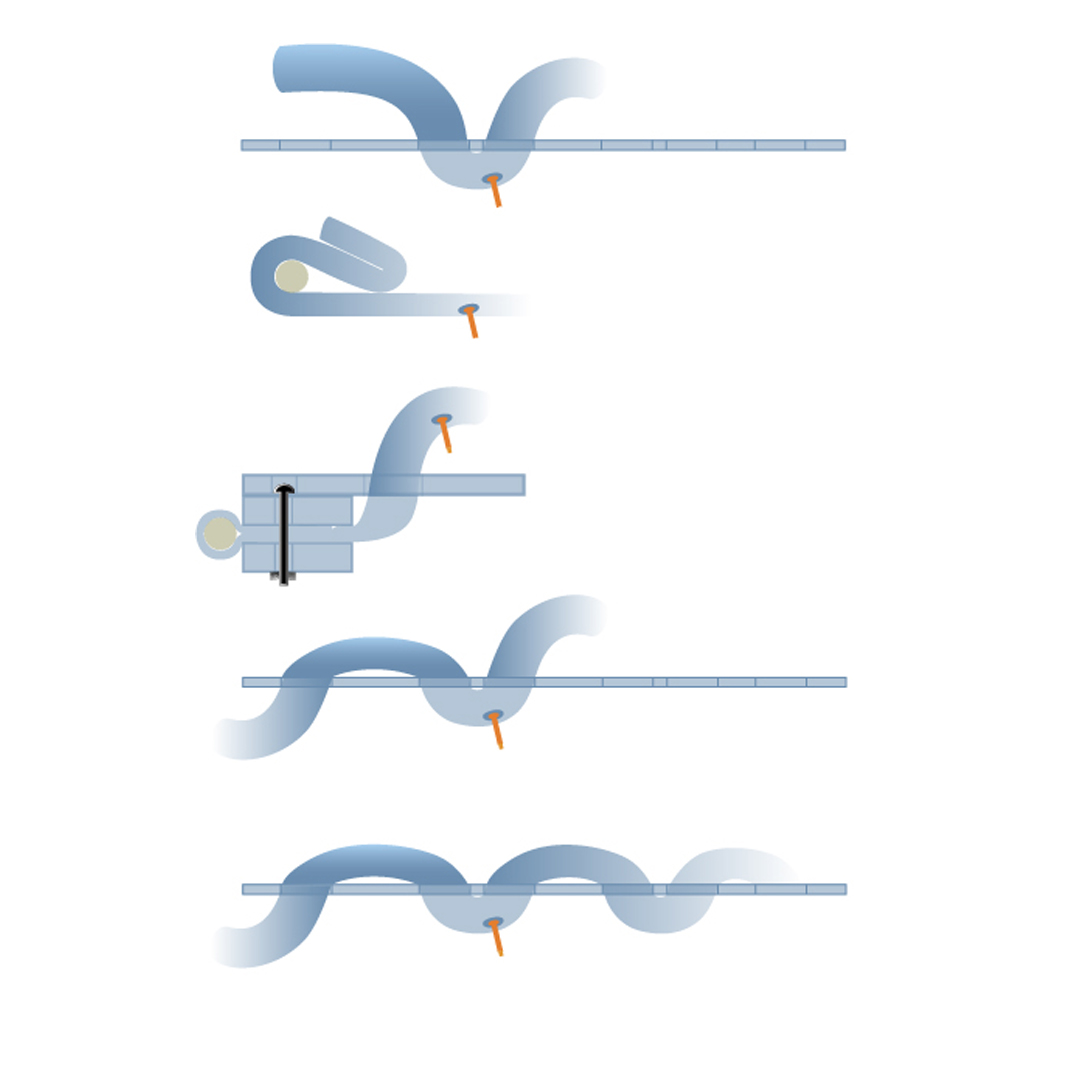

This project was born as a desire to give a second life to this product: by installing a patch, by welding, or by pressure joints, which requires little heavy means and allows this raw material to be reused.

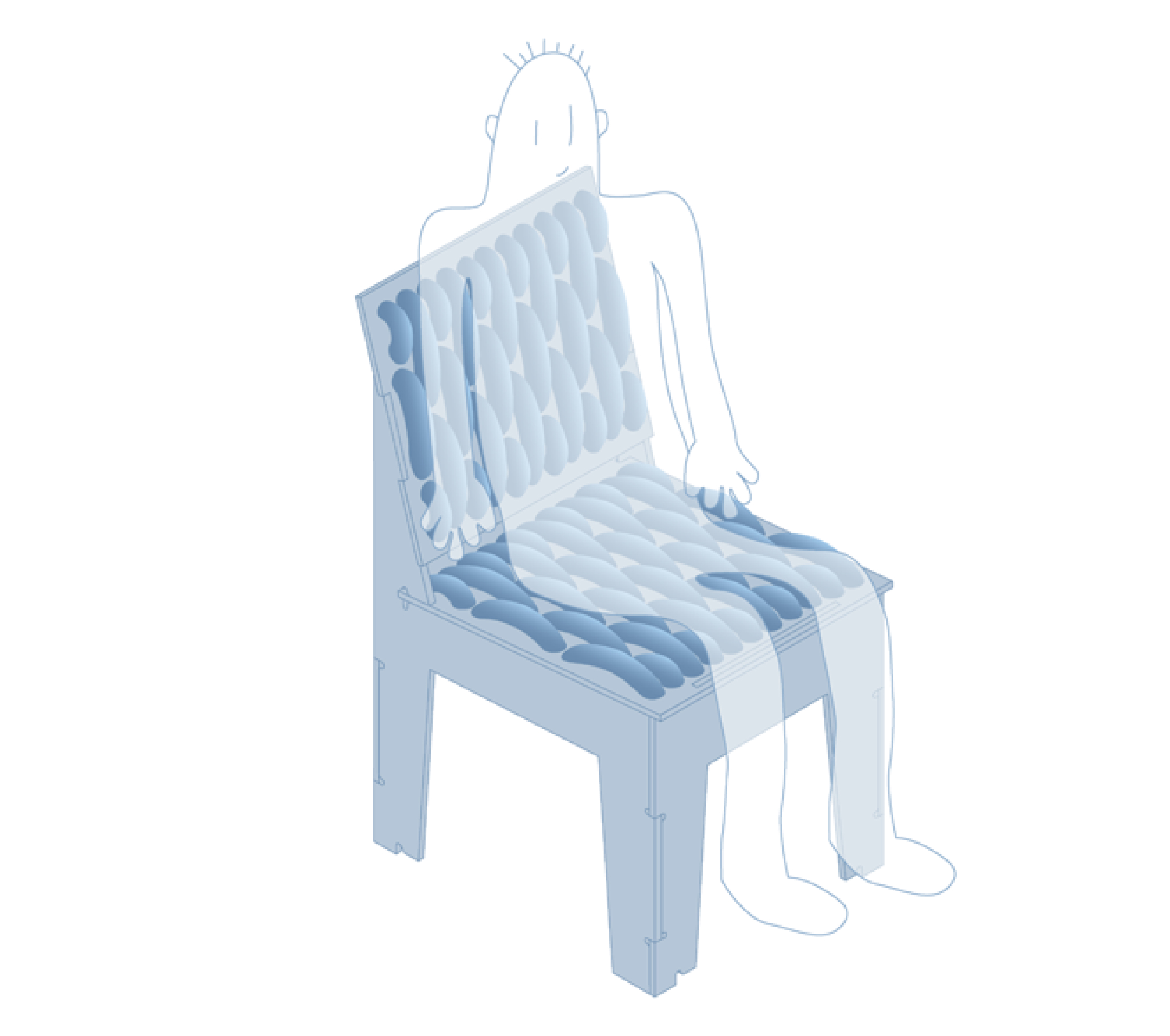

Once repaired, the inner tube remains structuring and malleable, which allows me to generate inner tube weavings like quilting. Thus, the comfort element is intertwined with the support element, with an aesthetic between cycling and cross stitch.

With this weaving comes a work on panels from falls in which comes to be machined a grid defined by the diameter and the elasticity of the air chamber. This tray serves as a support for braiding to produce a quilted and comfortable object.

By the logic of inflation, I can therefore change the shape of my object and its proportions without heavy means, it is a logic of lighter manufacturing, much more economical and more reasoned. This concrete application, associated with an open source manual, allows everyone to play on the parameters of comfort by inflating, but also to imagine other applications.