About the project

This project suggests how bioprinting bacterial cellulose using a modified variation of the FRESH protocol can be used to tackle the root of the problem with today’s supply chain in fashion, i.e., the assembly type of manufacturing. We suggest a new method that drastically reduces the environmental impact and gives designers and customers control of the process of growing garments from the initial seed to the finished product.

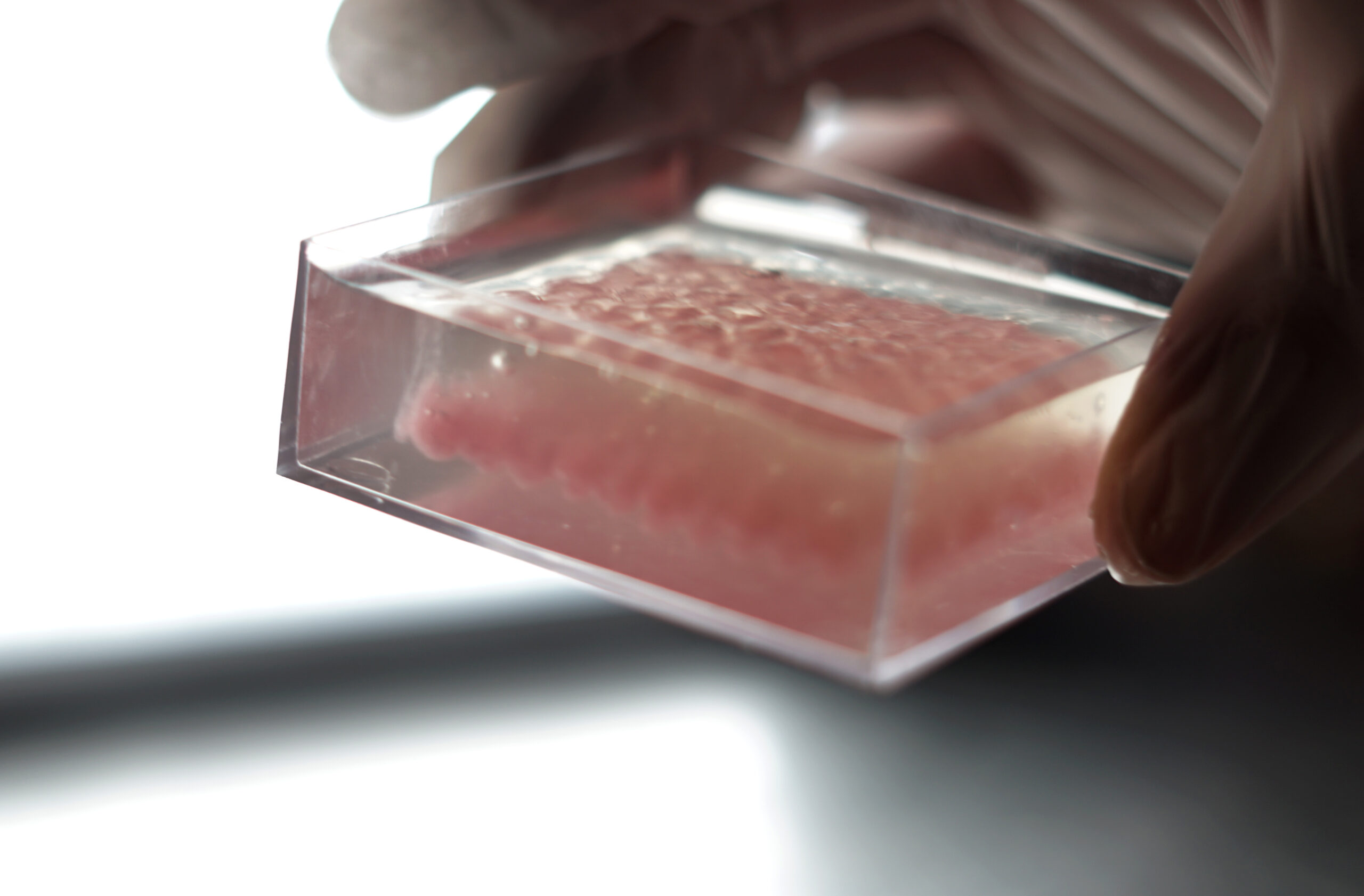

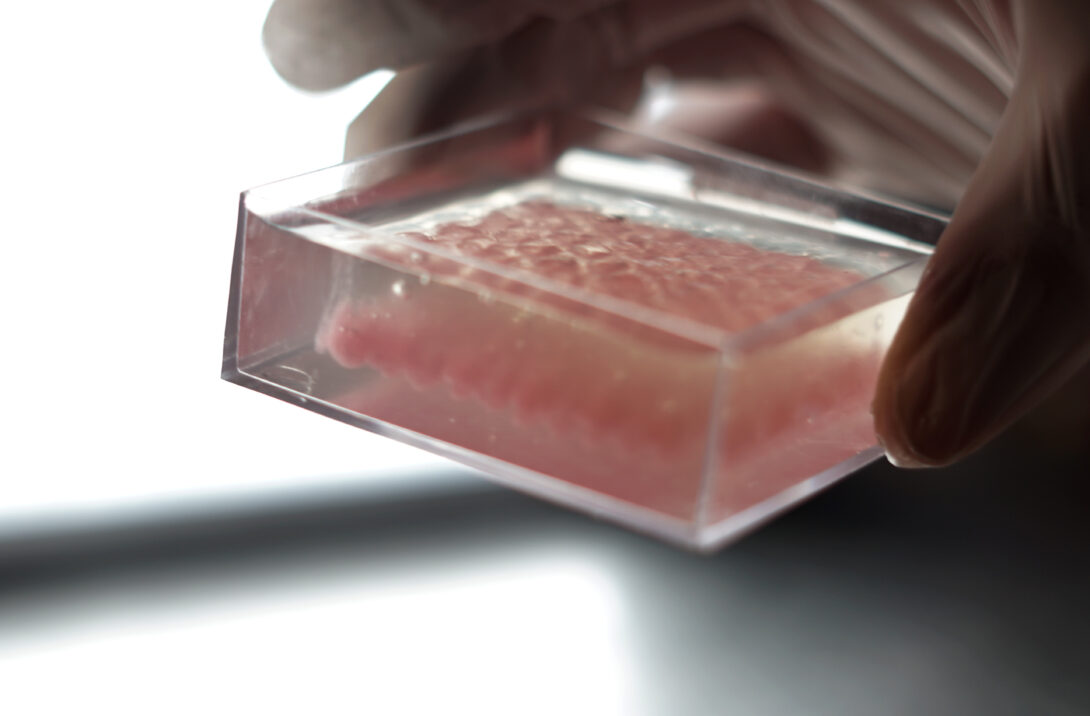

The FRESH protocol (Freeform Reversible Embedding of Suspended Hydrogels) is a technology that was initially developed for tissue engineering: it uses a gel bath as support for the bio-ink. The gelatin support bath acts as a temporary scaffold, allowing the printed layers to be precisely positioned without collapsing during the printing process, and creating complex, three-dimensional structures in 3D space.

Interestingly, this highly complex (and expensive) technology developed for medicine can be adapted for the fabrication of 3D garments and has the potential to become a much faster, more adaptable, and cheaper process than today’s complex supply chain.

By rethinking the notion of mass production and hacking existing robotic hardware, we can tap into existing networks of local businesses, breweries, and maker spaces and build a distributed network of independently run distributed factories.