Cities are consuming 60-80% of all global natural resources, producing 50% of all global waste and account for 75% of greenhouse gas emissions (Camaren, P.; Swilling, M. Sustainable, Resource Efficient Cities-Making it Happen; UNEP: Nairobi, Kenya, 2012).

With growing populations in cities these challenges are gaining ground, but at the same time facilitating a potential of reintroducing local manufacturing, local consumption and cities as urban mining facilities of resources. As a way to bridge the circular economy (emphasis on profit), sustainability agenda (emphasis on planet) and urban local manufacturing (emphasis on people), the concept of distributed design becomes very relevant.

Distributed design and urban local manufacturing is not equivalent with protectionism, closed borders or national conservative ideologies. From a distributed design perspective diversity, peer-collaboration and open design practices is the core of how localized sourcing of primary or secondary resources, local urban production and global connectivity can be realized. (Tsui, T.; Peck, D.; Geldermans, B.; van Timmeren, A. The Role of Urban Manufacturing for a Circular Economy in Cities. Sustainability 2021, 13, 23, p. 3-4). In times of global turbulence and uncertainties minimizing dependencies in global supply chains becomes precious, but at the same time enables the potential to foster global collaboration and the development of green, thriving and engaging local communities and economies. (Tsui, T.; Peck, D.; Geldermans, B.; van Timmeren, A. The Role of Urban Manufacturing for a Circular Economy in Cities. Sustainability 2021, 13, 23, p. 4)

The potential of distributed design and production in design, fabrication and collaboration in many ways still needs to be systematically validated on local and global scales, and as a reel alternative to the traditional ways. However, we understand a rise in local and European cases that investigate, incorporate and test distributed models in design and fabrication. There’s undoubtedly an interesting move towards decentralized small units and micro-factories and producer networks – Make.Works, Distributed Design Platform, Open Desk and Fab City – just to name a few initiatives and cases. (Tsui, T.; Peck, D.; Geldermans, B.; van Timmeren, A. The Role of Urban Manufacturing for a Circular Economy in Cities. Sustainability 2021, 13, 23, p. 3-5)

In the blogpost we will present an inspiring case from Copenhagen, Denmark, that embeds open design practices, distributed design and fabrication models and digital fabrication as core values in both the company and products. The purpose is to shed light on how locally anchored fabrication models and the concept and methodology of distributed design can be part of the solution of developing circular cities.

Local case: Helium Living x Quirky Moose

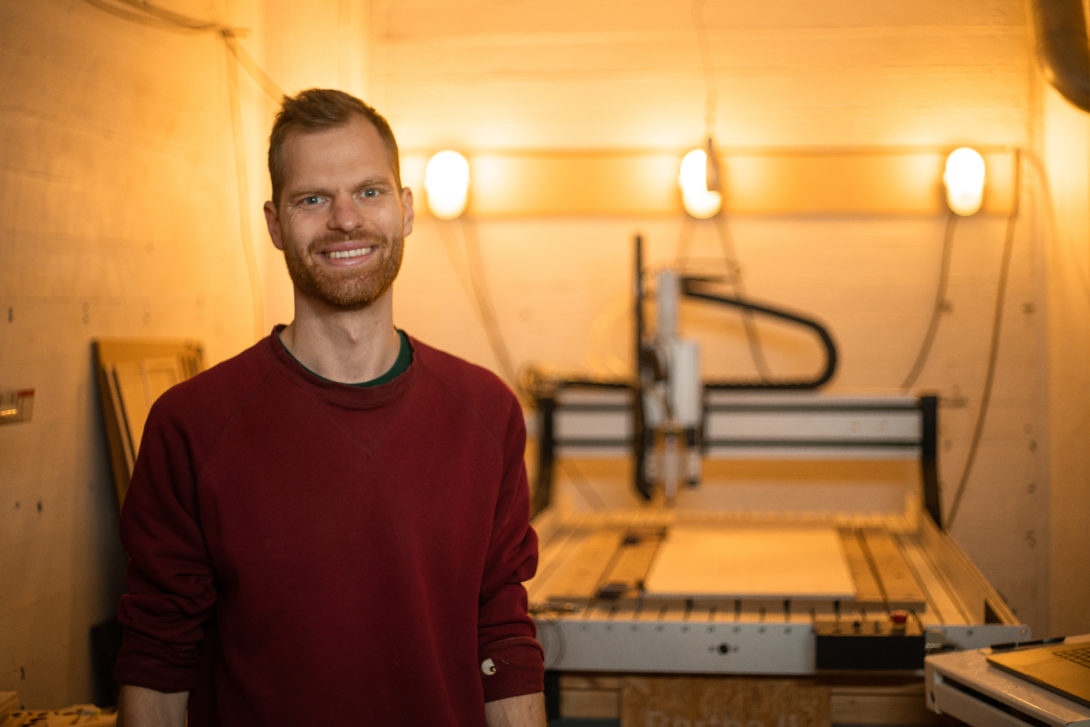

When Aske Fabech was working as head of products at a scale-up within tech he dreamt about positively contributing to solving the climate crisis within the area of the built environment. However, without a formal degree from the university and no prior experience in building furniture he set out with a clear purpose – to create furniture for small space living that would allow people to live and take up space according to the planetary boundaries, sustainable living and global equality.

However, Aske did not have the funds to set up a workshop with specialized equipment to prototype and produce such furniture. Furthermore, he lacked input from likeminded people with other professions and skills than his own.

That’s when he decided to become a member at his local professional workshop/makerspace, Viadukten, run by Maker in Copenhagen.

In the shared workshop facilities he met a curious and interested community, had access to highly specialized machinery and could develop prototypes with promotional events to boost both the feedback and the brand knowledge. When Aske began working in the space, he quickly found that sharing ideas and actively seeking feedback on prototypes and new product ideas was speeding up the time from idea to prototype and product.

However, most shared workshops are not equipped and set up to do production series of larger quantities. That’s when Aske sought advice from Maker for alternative business models and ways of designing for local production and distribution of designs. Maker, as part of the distributed design platform, was able to point Aske in the direction of best cases and inspiration from across Europe. This led directly to the forming of a partnership between Aske (Helium Living) and Stig (Quirky Moose) – a local manufacturer and carpenter in Copenhagen.

The results of the journey, the approach, the partnership and the products can be found here: https://heliumliving.dk/ and https://maker-effekt.dk/artikler/aske-haslund-fabech/

Story by Asger Nørregård Rasmussen / MAKER