About the project

Dehypaper is a solar dehydrator designed for efficient and sustainable recycled paper drying. Featuring a modular and adaptable design, Dehypaper offers a tailored solution harnessing solar energy to accelerate the drying process of paper, while embracing a distributed and open design for accessibility and replication.

“Papermaking” with the reuse of paper is a fundamental practice for preserving the environment and conserving natural resources, but drying recycled paper is often a time-consuming and intensive process. Handmade paper drying is a practice that dates back to antiquity and is widely used in various regions of the world, each employing different techniques in response to different climates and traditions. Evidence has been found of methods such as the use of molds in the Far East, “drying-lofts” in Europe, and specific techniques in places such as Nepal, Japan, China, among others. To address this challenge comes the recycled paper solar dehydrator, an adaptation of solar dehydration equipment designed to speed up the food drying process by using solar energy efficiently and sustainably. This machine is able to capture the sun’s heat, keeping it insulated and promoting air circulation to speed up drying, resulting in significant benefits for the environment.

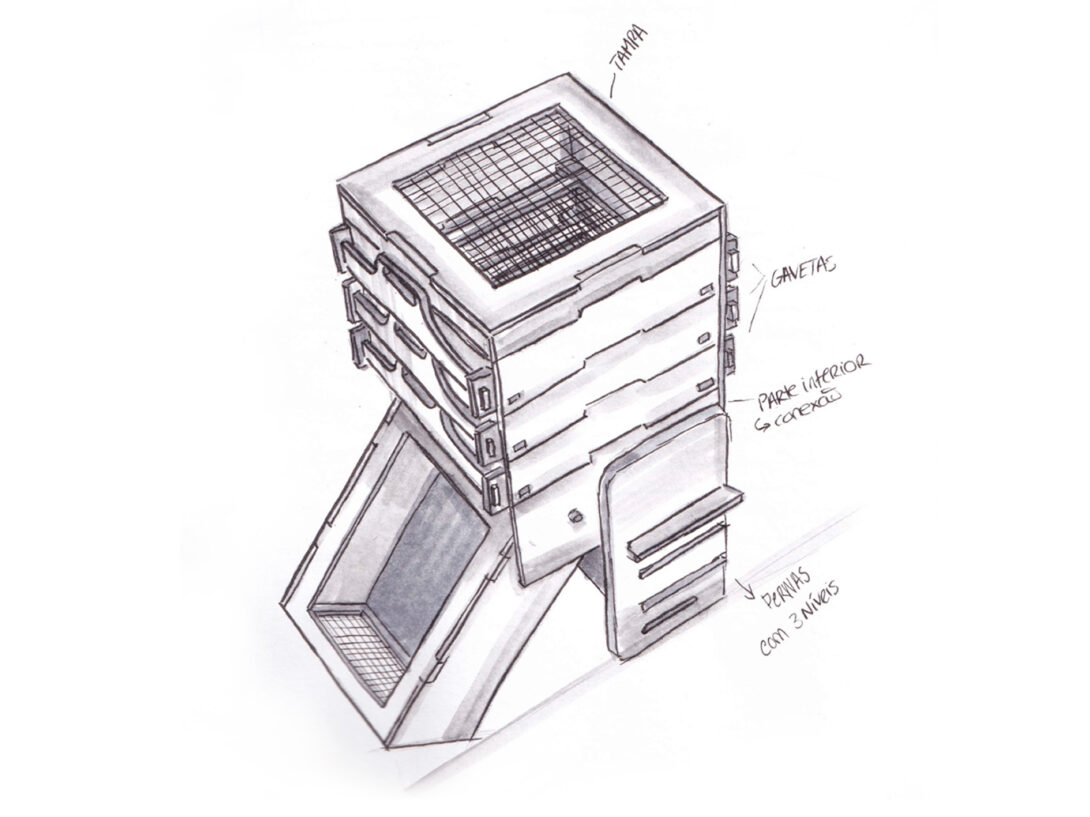

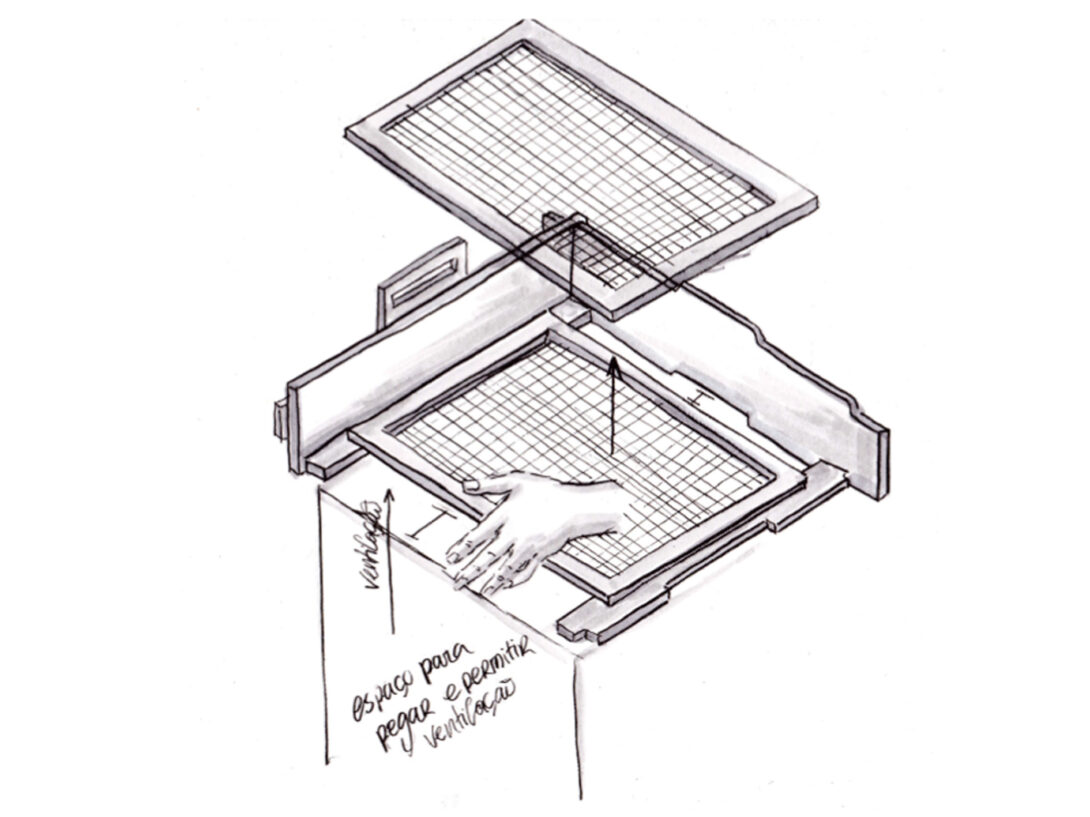

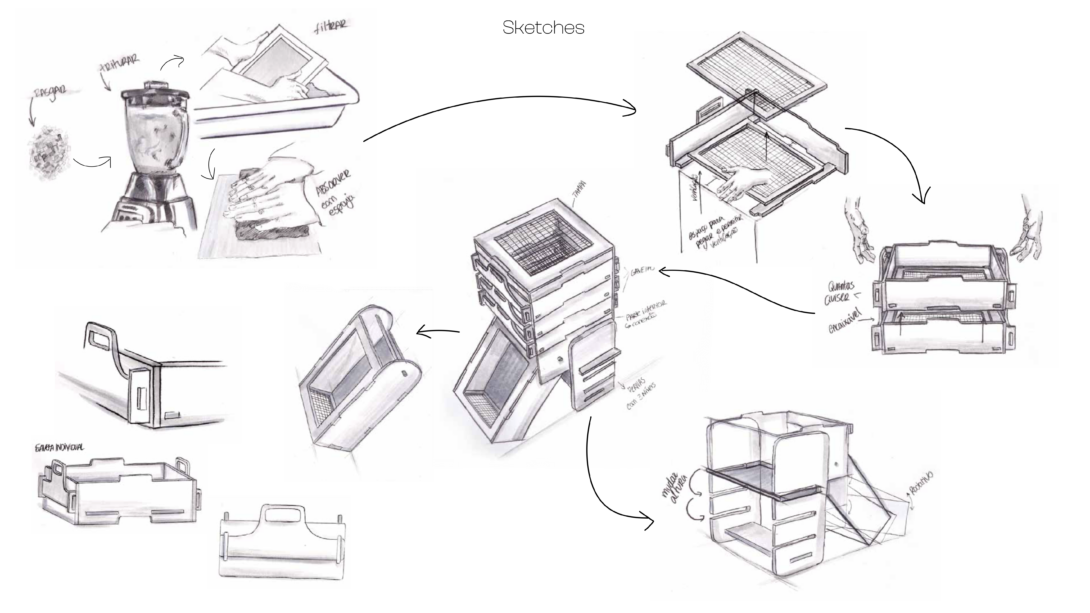

The idea behind the solar dehydrator for drying recycled paper is to harness the sun’s energy to speed up the paper drying process. This product ultimately benefits the environment both by contributing to sustainability and by reducing environmental impact. Heat is used as the main source of energy, a renewable and clean source, which does not emit pollutants or deplete non-renewable resources in its use, unlike fossil energy sources. It contributes to reducing solid waste, meaning less paper is wasted and less waste goes to landfill. It also helps to save natural resources, such as trees, which would be needed in large quantities for paper production processes using natural raw materials. The machine would be divided into 3 distinct zones, the first zone being a solar absorption area, which consists of a dark surface designed to absorb solar energy, converting it into heat. This heat is then isolated and kept inside the dehydrator, creating an ideal environment for drying the paper. The drying area is made up of partitions, with an integrated mesh frame in the shape of an A4 sheet, capable of helping to capture the paper fibers, maintain the shape of the sheet, store the paper, enable good adhesion through the cellulose in the composition of the paper, without the risk of wrinkling and requiring presses to do so. The choice of A4 size not only stands out for its efficiency, but also for its practicality, as it is more economical in terms of space and materials, making it easier for the user to move and stack the boxes. It should be noted that temperature/time are characteristics to be taken into account by experimentation depending on the weight of the original sheets and the amount of fibers collected for the board.

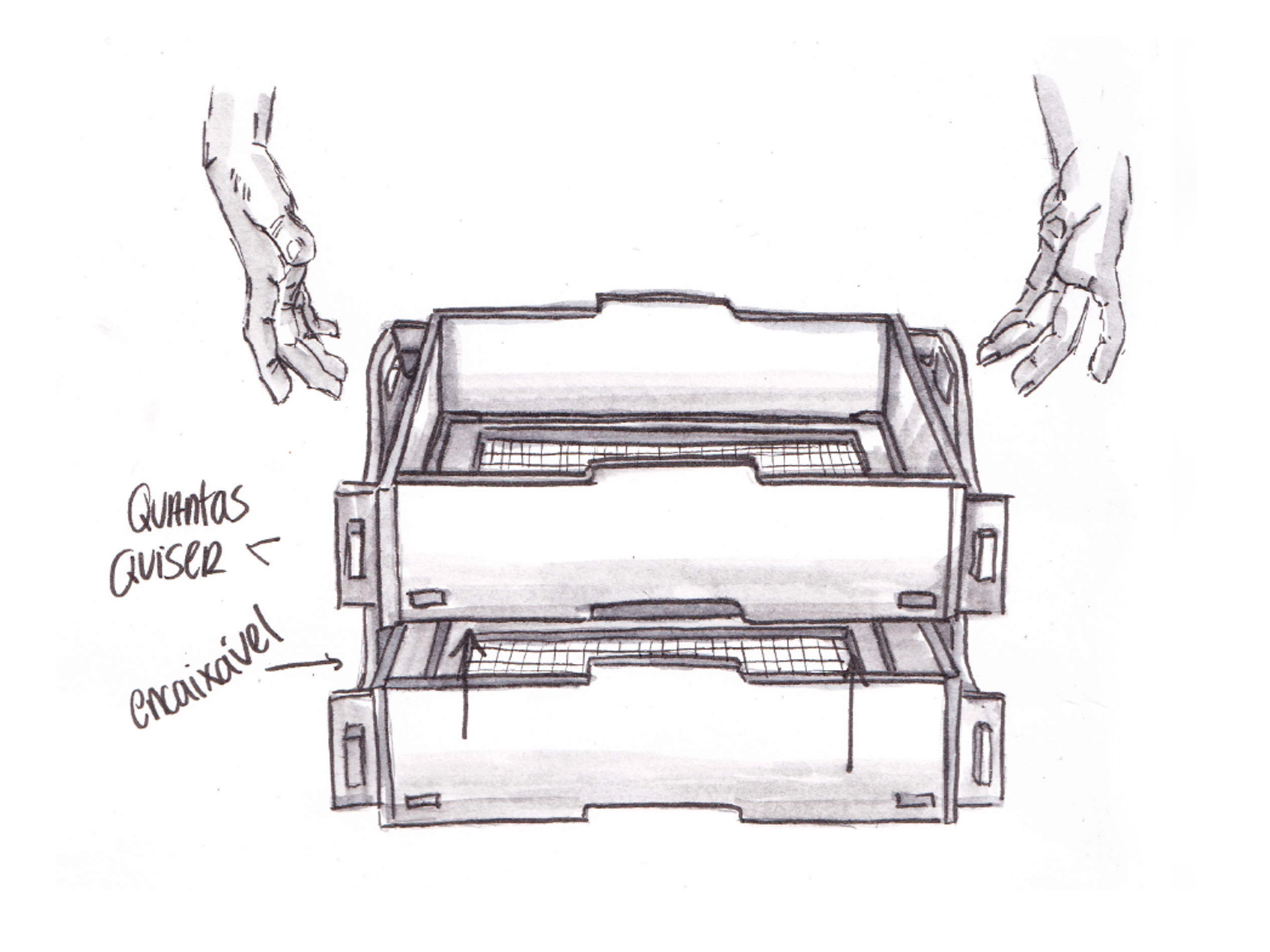

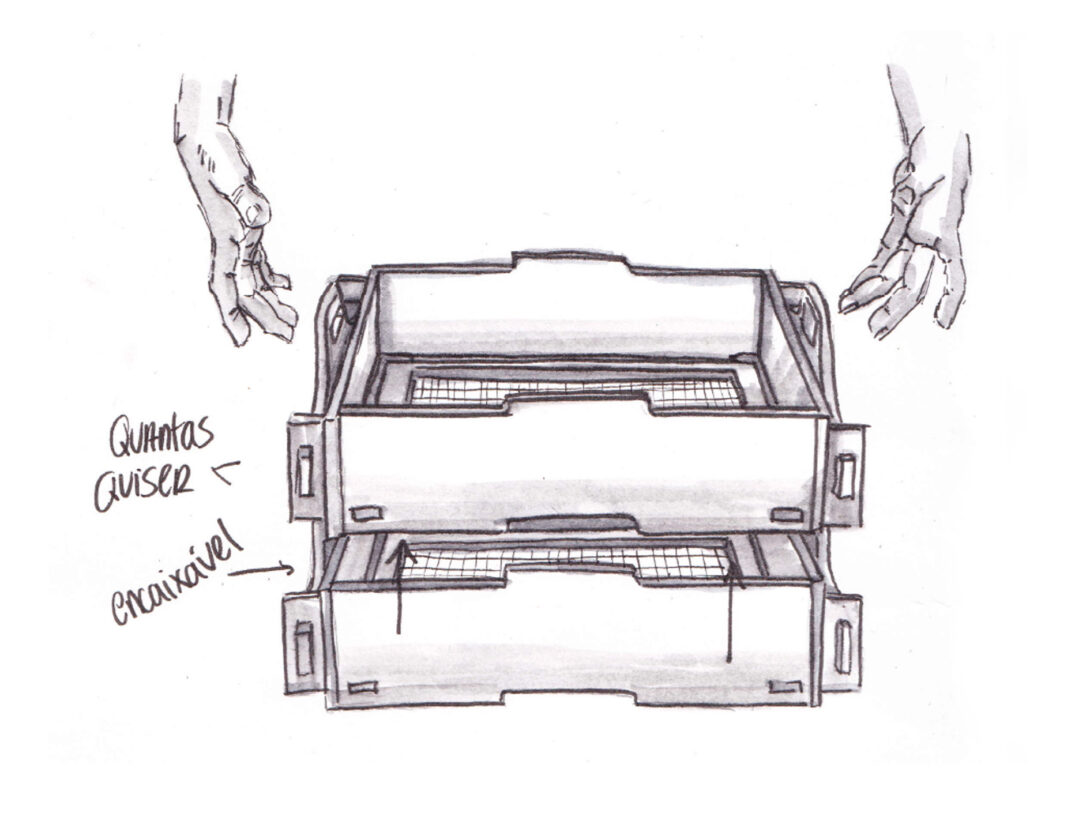

Each partition is equipped with a mesh frame for drying the paper and can be stacked on top of the others. This allows the user to add or remove dividers according to the demand for paper to be processed. This customizable approach offers a versatile and efficient solution that allows for recycled paper production tailored to the user’s specific needs. The heat absorption box, on the other hand, has an articulated design that allows the angle to be optimized for efficient capture of solar energy. This strategic adjustment not only takes into account the position of the sun throughout the day, but also adapts to seasonal variations, ensuring effective heat absorption all year round. The heat coming from the absorption zone is evenly distributed throughout the machine with the help of air circulation, designed to allow moisture to escape and fresh air to enter, promoting a natural air circulation, where warm air rises and moisture is removed, speeding up the drying process. The dehydrator was conceived with a distributed and open design, with an emphasis on ease of replication and allowing the user to adapt it according to their needs. The system is designed to be accessible and adaptable, using MDF boards and cuts made on CNC machines, allowing the community to reproduce it easily.