We’re excited to introduce eight creative talents who had the opportunity to materialize their ideas during the Distributed Design Residency at Happylab Vienna. Following an Open Call in July 2022 these makers & designers were chosen to take part in the program based on feasibility, design and social/environmental impact of their submitted projects. From September 2022 to February 2023 they will make use of the machines, infrastructure and their own workplace within the makerspace and get feedback as well as coaching sessions on how to get the best out of the digital fabrication tools.

We were able to meet with all of them and get a glimpse of the current status of each project. Their works will be presented at Happylab in a joint exhibition in March 2023!

Alles Spitze? – Stephanie Edelhofer

After her training as a clothing technician and subsequent studies in Fashion & Technology, Stephanie Edelhofer is looking for ways to rethink fashion production. As part of her bachelor’s thesis, Stephanie already worked in a makerspace to create lace-like patterns with the laser cutter. “Imitating” the aesthetics of lace, which in earlier times was reserved for the wealthy classes of society, digital fabrication now makes this textile accessible to all.

During the Distributed Design Residency, Stephanie would like to build upon the knowledge she gained in these previous projects and, in addition to lace-like patterns, also take other textiles as a reference. By experimenting with different digital fabrication technologies and different materials, she wants to make clothing production more accessible for everyone – regardless of prior knowledge or sewing skills. In particular, Stephanie would like to look for ways to avoid classical sewing patterns and try out new forms that don’t require sewing.

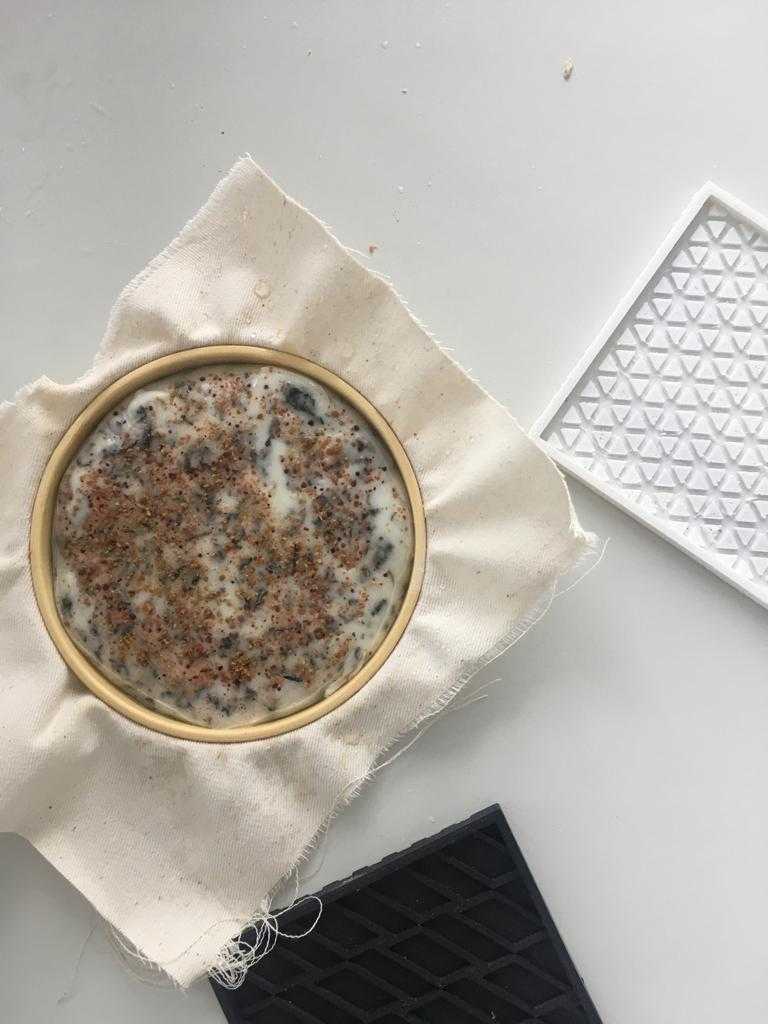

Experimenting with biomaterials – Cindy Fodor

Cindy Fodor is a fashion designer who recently graduated with her first collection “ENIGMA” that combined 3D printing and laser cutting techniques with traditional craftsmanship. At Happylab, Cindy wants to experiment with biomaterials in the next few months and create her own textiles that can be further processed with the laser cutters in the makerspace. She will document her experiments and create an open sample library for the biomaterials she fabricated – including recipe instructions so that other designers and makers can also benefit from her findings.

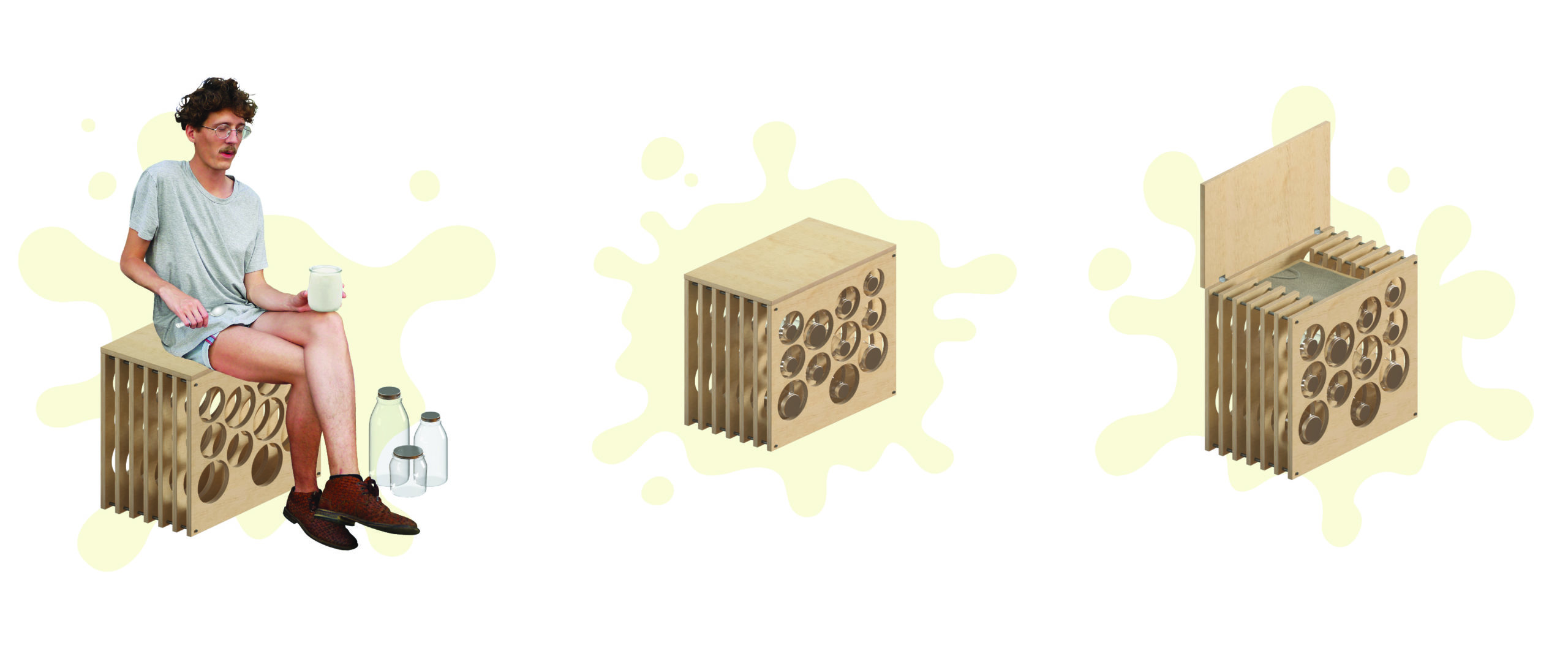

MÜLL ABER COOL – Maria Levitskaya & Daniil Chechin

Maria Levitsky and Daniil Chechin studied architecture in Vienna and both like to create stuff in the makerspace. In the project they are realizing within the Distributed Design Residency, Maria and Daniil are tackling the topics of reuse and recycling.

Most consumed drinks or liquid food come either in plastic or glass bottles/jars. Bottles that end up in homes must be cleaned and returned to a specific container or back to the shop in order to be properly recycled. Lack of space or no efficient storage makes it harder to collect plastic or glass garbage before recycling. “MÜLL ABER COOL” aims to find a new type of furniture for the temporal storage of recycled goods that combines functionality and aesthetics. Maria and Daniil are currently working on two different prototypes: “Bottlebox” – a stool that collects reusable glass and “YesPress” – a stool that enables us to collect and crush plastic bottles.

Pregnancy massage table – Katharina Gleißberg

Katharina Gleißberg is a massage therapist who likes to tinker and realize her own DIY projects with digital fabrication tools in the makerspace. In the course of her professional life, a certain interest and focus clientele has emerged – Katharina is working a lot with pregnant women. Only her massage table has stayed the same, although the requirements for it have changed as well. So the idea to build a modular massage table herself came up – including a cutout for the pregnant belly, height adjustable parts and add-ons.

During the Distributed Design Residency, Katharina will develop the design of the massage table and build her first prototype on the CNC milling machine at Happylab.

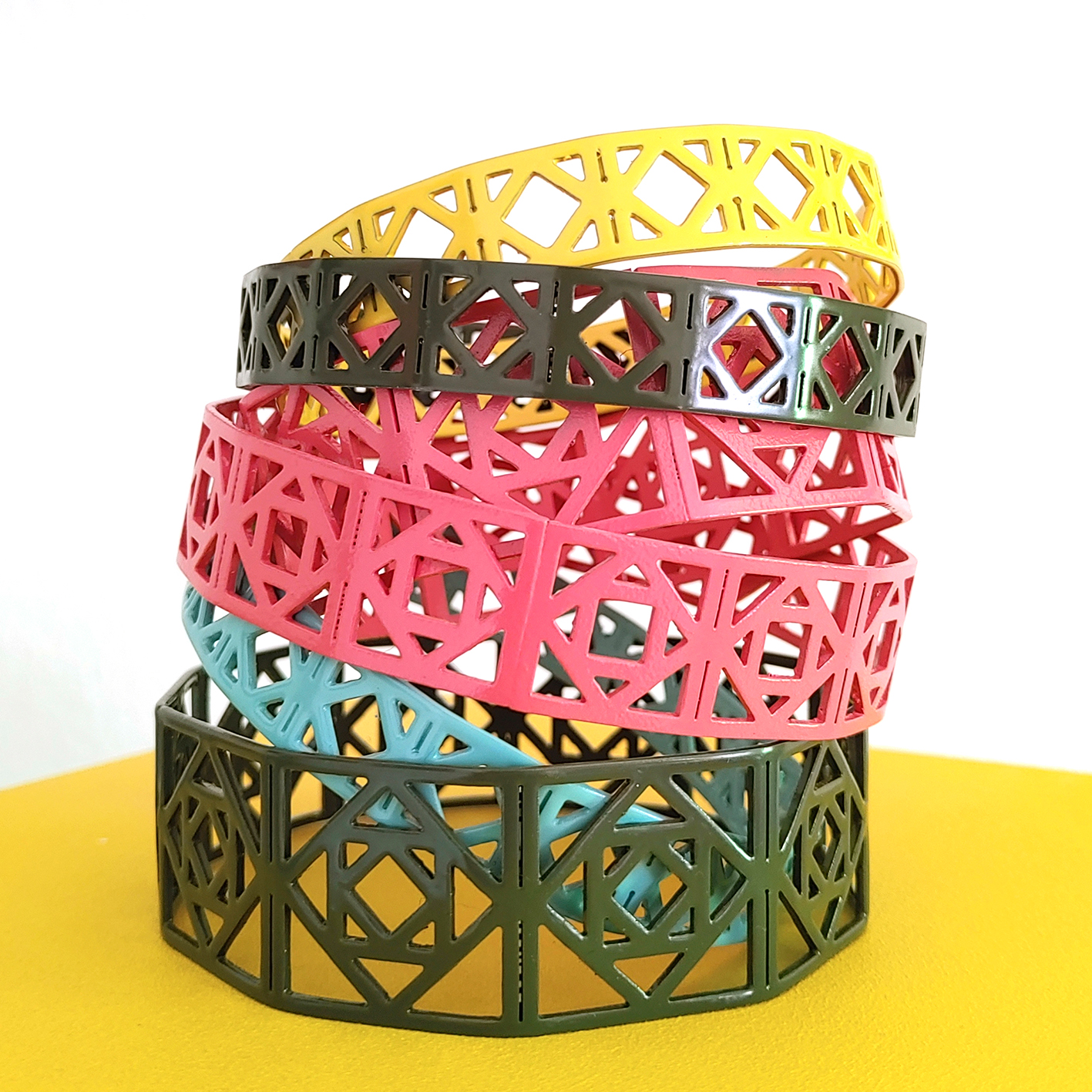

QUADRAT hoch 2 – Konstanze Prechtl

Konstanze Prechtl is a freelance artist and jewelry designer based in Vienna. Her designs are made out of laser cut metal which she bends and powder-coats in different colors or covers with fabric. So far Konstanze has commissioned the laser cutting of the metal parts abroad, but she would very much like to do it herself – eliminating unnecessary transport and keeping production local. In the next few months, Konstanze will further develop her jewelry collection with the metal laser cutter and other tools in the metal workshop at Happylab.

TMBR Scooters – Katrin Batko

Scooters and e-scooters have been part of the cityscape for several years. But they all look the same and hardly differ from each other externally. While the bicycle market offers all kinds of colors and shapes, there is hardly any choice on the scooter market.

Since the fall of 2021, Katrin Batko is working on an E-Scooter prototype made of sustainable materials such as wood and bamboo, whose modular elements can be produced regionally. Within the Distributed Design Residency, Katrin’s goal is to further develop her prototype – a sustainable E-Scooter that stands out visually and impresses with distinctive design.

Wooden bikes for kids (that every adult would like to have had!) – Robert Poeckh

After school Robert Poeckh decided against studying industrial design. Instead he studied business administration at WU Vienna and started to work in a Viennese advertising agency. But the thought of designing and developing his own product has not let go of him. That’s why in 2018 he started to produce balance boards and other small projects for friends, family and himself at Happylab. This led to his current project which he wants to tackle during the Distributed Design Residency: wooden bikes for kids with a distinctive design! In the next few months, Robert will finish a first small-scale production of the wooden bikes using the CNC milling machine and the wood workshop at Happylab.

Story by HappyLab Vienna