Open Food Factory is an initiative conceived by Polifactory, the makerspace Fab Lab of the Politecnico di Milano, dedicated to the design of open-source solutions for plant-based food with a focus on fermentation and distillation.

Sixteen designers, selected through the Open Call for Ideas, ideate three concepts of fermenters and distillers working as makers in residence at Polifactory, which supported them in developing the HACKO, BREATH, and OLEA projects.

Nukazuke is a Japanese pickle produced by fermenting vegetables in rice bran. Nukazuke is a healthy food process that is hundreds of years old. The lactobacillus colony that proliferates in the nukadoko (the rice bran bed) transforms the vegetables into pickles. The lactobacillus culture must be healthy to ensure that the fermentation works. Preparing Nukazuke requires constant effort and care, experience, and knowledge.

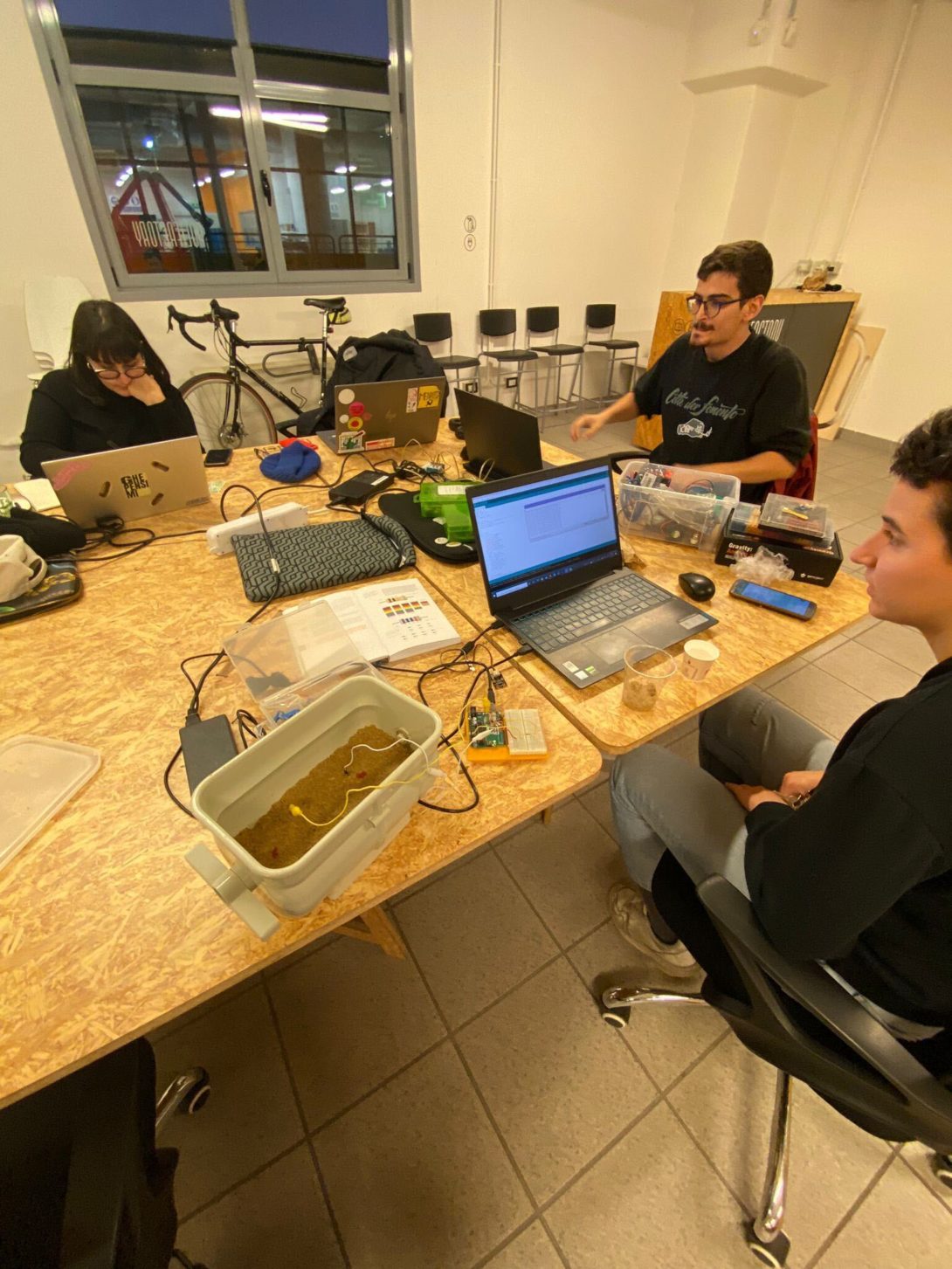

The HACKO project explores the potential of distributed design and digital fabrication to make nukazuke a more accessible, adaptable and reproducible process in different cultures and countries. The Japanese entrepreneur Kentaro Sohara and a group of designers – Giovanni Bruno, Federico Denni, Martina Comola, Andrea Somenzi and Gaia Rubino – developed an open-source kit to produce nukazuke from ordinary plastic boxes by using the following elements: a set of small trays designed to regulate the drainage of liquids from the nukadoko, a multi-purpose tool that can support the handling and maintenance of the nukadoko, and a digital device that can monitor the humidity and temperature parameters needed to maintain the ideal conditions for fermentation.

BREATH is a project conceived and developed by the young designers Alberto Ambrosini, Daniele G. Fotia, Alice Monti, Vittoria Pagliaroni, and Luca Vergani focused on lacto-fermentation, a method of preservation that does not require the use of electricity and allows each part of the food to be enhanced, intensifying the flavours and reducing waste.

BREATH is a three-elements system: a cap containing a valve and two silicone membranes designed to ensure that no liquids leak out, and to replace ordinary glass weights used to hold fermented food in the correct position. All the BREATH elements can be easily 3D printed.

OLEA is a system devised by Giulia Chiggiato, Irene De Biasi, Chiara Guarino, Federico Montini, and Vittorio Rinaudo that experiments with non-alcoholic distillation processes by adopting an approach influenced by the practices of making and citizen science.

OLEA designs and makes ‘reversible adaptations’ of ordinary household items: a steel pot with a lid and colander, a steel basket for steaming, and a glass jug equipped with a small tap. OLEA has designed the different elements to facilitate the passage and separation of essential oils, hydrolats (the perfumed waters), and water, including a double outlet, tap to separate essential oils, hydrolats, and water, and a component that allows the copper coil to be correctly positioned in the glass container, facilitating distillation control.

Story by Polifactory