The Distributed Design Challenge Exhibition is a progressive initiative that aims to celebrate and support the rise of distributed design, through an exhilarating five days of experimentation, prototyping and production.

For this year’s London Design Festival, FandCo were partnering with Tala, an award winning lighting brand founded on the premise that good design can help mitigate climate change.

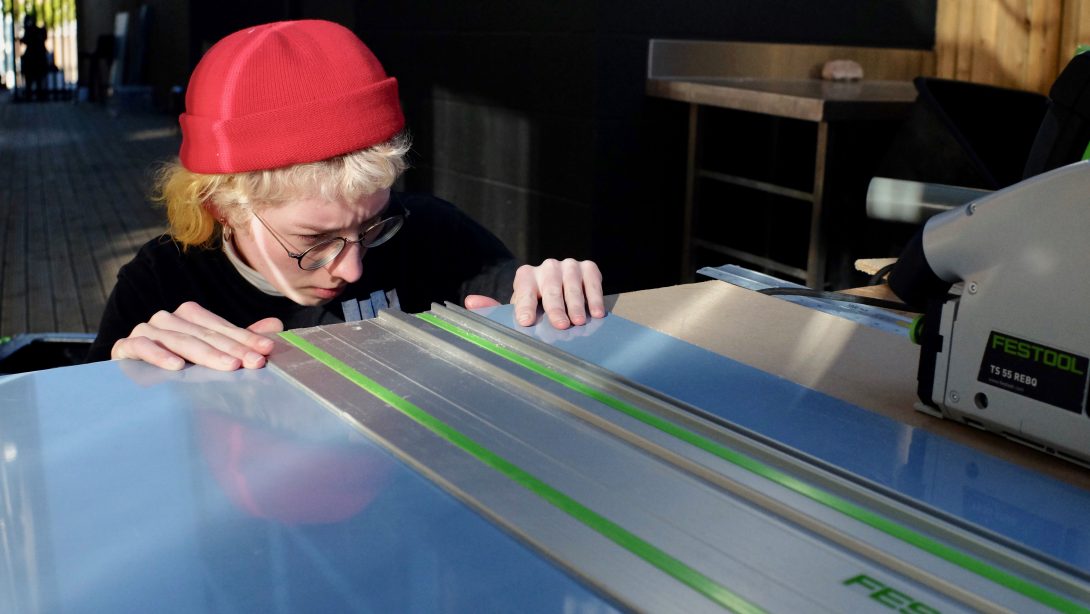

FandCo and Tala worked with 8 emerging designers and makers using Tala’s sustainable, LED bulbs as inspiration to create lighting fixtures that can be manufactured anywhere in the world, using accessible digital manufacturing techniques. With a time limit of five days and by using only 3D printers, CNC machines and laser cutter the creative talents responded with amazing designs to this challenging brief.

During the workshop Artists like Coco Sato, known for translating traditional japanese aesthetics into modern art forms, and Award winning Designer Tom Raffield were giving intimate talks and supported with their knowledge.

The participants went from design concept to exhibition within one week, and the results are currently displayed at Tala’s new global headquarters, Tala Studios. (Vyner Street, London). Four of the winning designs were awarded and prototyped and the Exhibition of the four Distributed Lamp Designs will be on display at Tala Studios until October 31st – so pop in!

We present the winning designs of the Distributed Design Lamp Challenge and their designers below. The Lamp Designs were selected by their progressive and innovative use of material, and achievability while creating value for people and society or companies.

Milo McLoughlin-Greening (Graduated 2018 from MA RCA Design Products):

“Distributed Design is a methodology that has an extremely academic grounding with utopian ideas at its core. With my entry I have aimed to create a system which can take these principles out of academia, with a design which could be implemented right now with access to one tool.

My personal design practice is focused on how design can be used as a grassroots tool for systemic social change.I am interested in how the use of locally available materials and production methods can improve social cohesion. With this in mind I am keen on creating a realistic path for distributed design rather than dreaming about its overarching potential. The two key elements can be 3D printed anywhere on the most rudimentary machine and can then be paired with any number of other locally sourced elements to create a carefully considered but simple object. With the same two printed hubs anything from a small table lamp to an oversized hanging light can be easily produced with no additional tools, or they can be seen as a starting block in the development of something far more complex.”

Ewan Alston (Graduates 2019 from MA RCA Design Products):

“This project features two prototype floor lamps that represent alternate approaches to distributed design.

The first prototype is a proof of concept to remind us that distributed manufacturing does not have to mean digital manufacturing. It attempts to show that we can achieve an interesting, functional design with local materials, simple instructions and only the most basic of tools. The lamp combines found objects with common hardware store items, and includes PVC piping, elastic bands and a log, though these parts serve merely as examples and the design should be customised for the user’s location –– a previous version included aluminium pipe for the stand and a London brick for the counterweight.

The second prototype represents a more polished approach that takes full advantage of digital distribution, employing 3D printers for the basic components. But the key objective here is to go beyond the ability of the machines, combining printed parts with other (easily sourceable) elements that bring playful, lively interactions to the lamp. The printed parts at the neck of the lamp work with elastic bands to create a satisfying nod of the lamp’s head, while a hidden inline switch allows the lifting motion to activate the bulb. Lifting the lamp’s head turns the bulb on; bowing its head turns it off. This creates a floor lamp with personality that longs to be used.”

Chifen Cheng (Graduates 2019 from MA RCA Design Products):

“Soft Touch is a table lamp designed with a borderless distribution and reproduction in mind. The traditional process of manufacturing overseas with global distribution is no longer sustainable for our planet. Resource depletion, plastic oceans, and global warming are some of the reasons why designers need to be mindful of their design decision and the aftermath.

By sharing its digital data, Soft Touch can be produced anywhere around the world, and be made with locally available materials and machinery. With different types of data, the maker can choose between 3D printing, CNC or laser cutting processes, depending on the budget and timeline. Plastic, hair, or corn husk can be used for the bristles. Alternative sheet materials can be applied for the ring design and the lampholder if a pipe is not available.

While making the lighting fixture customizable to appeal to different demographics, cultures, and trends, the lamp offers a timeless and tactile connection between the designer, the maker, and the user. The sensory integration adds a softness and warmness to the digitally made good. This distributed design process is a stroke away from making a difference.”

Janaki Ranpura (Graduates 2019 from MA RCA Innovation Design Engineering):

“How can we use distributed manufacture to propagate strangeness? How can we complicate regularity?

Distributed manufacture seems to demand simple, replicable designs. How, within these, might we show the uncertainty of our current partnership with the environment?

This lamp idea was inspired from a piece of packing material. The material is made to be regular and robust, and its design allows it to warp in uneven ways. The look as well as the metaphor inspired the Frag Lamp. The name comes from the Latin frangere, to break, which is also the root of the word fragility. The structure is broken into three functions: the seating for the bulb at the center, the verticals that generate enough space for the bulb to shine, and the covering that fractures the light into a more complex pattern. It is the outer covering that offers the space for great customization — you can hang nearly any old flotsam off the surface, creating an irrationality encouraged by the design.

Readily available materials in easy sizes have been the constraints: the Tala bulb used is the one that comes in the most common shape, the jagged verticals nest together to exploit as much of a flat acrylic sheet as possible, the paper and packing material on the outside is easily sourced. The Frag Lamp uses a replicable substructure to make a canvas for local expression of materials. The designer’s motivation to make designs that are globally accessible comes from living a life in many countries and knowing the work it sometimes takes to decipher cultural codes. Her background in shadow puppet theater is also noticeable in the design.”

Josie King (Graduated 2018 from BA Goldsmiths Design):

“My designs are often inspired by the everyday, and this lamp for Tala was no different.

I love taking something familiar and placing it in an unfamiliar context as this can make us consider these objects differently. This lamp was inspired by trips through London at night, watching cranes loom overhead as their lights flicker on. These temporary fixtures of the city are present in every urban landscape yet are so commonplace that their functional beauty is often overlooked. I wanted to utilise the precision possible with CAD CAM as opposed to traditional craft for this distributable design. This delicacy and detail is only possible when using these machines, so I wanted to celebrate this unique quality of this process. It was important to me that this lamp not only looked like a crane but functioned like one too, using counterweights to mimic their smooth movements, highlighting the complex engineering involved in these graceful machines.

This lamp is designed for customisation, the file can be scaled to work for different sizes and lengths and can be cut in anything from ply to steel. My drawings may be developed into other crane-inspired lamp structures – tall tower crane floor lamps or a mobile desk crawler crane. I’ve used everyday objects to increase the functionality of the piece. The rotational base uses a castor wheel mirroring the lamp’s industrial theme. The counter weight is a concrete-cast coffee cup yet can be replaced with almost anything, encouraging experimentation with different weights and movement. Similarly the castor can be attached to any dense material as a base – I’ve used some rubble here that I found in the street; it’s a natural environment for a crane. I hope this lamp inspires people to look at their city in a different light.”

Dasie Buckle (Graduates 2019 from MA RCA Information Experience Design):

“The whole concept for this lamp was to create a sustainable, valuable and individual designed pieced which also fitted the outline of the brief; to be reproducible, valuable and distributable.

This design is flexible to fit into whatever lighting scenario an individual requires: it can be configured as a desk lamp, a hanging lampshade/wall light- three lamps in one requiring only three materials: wood, dye and a laser-cutter. I wanted to design and create a flat pack piece which was easy to move around but was sturdy once configured and an interesting sculptural addition to its environment. A core aspect and focus of this and my work is to be sustainable. It is a 0 waste piece which can be cut from recycled plywood/local wood found by an individual and then customised further using dyes from plants or foodstuffs collected locally.

I think it’s really important for people to be able to adapt and adjust a design to suit their needs and community, so though its reproducible by anyone in the world, of any age, it can then be tailored to suit an individual’s taste/scenario. With no fitted light source integrated, it also means it is flexible and reusable with the ability to be changed time and again.

For this collaboration with Tala, I didn’t want to cover the bulbs, which are beautiful objects in their own right. So the geometric shapes are softened by the fluid forms of the bulbs. A combination of materials and manufacturing/local making processes which celebrate individuality and an individual’s power to make – make their own structure and make a difference in the world through conscientious and sustainable practice.”

Elora Pierre (Graduated 2018 from MA Industrial Design CSM/UAL):

“For years, objects have been bought because we were attracted by their design and we liked something we saw. With the opportunities offered by distributed manufacturing and digital processes we can reverse that act: what if the starting point was the inherent quality and the positive impact of the material that the objects are made from? For the design of this lamp, I was driven by the use of a reclaimed and recycled plastic sheet, which offers a wide range of patterns and colours and can be manufactured by a CNC router. I wanted to explore the intrinsic quality of the material : by playing with stripes and different thicknesses, it creates a transparent effect, allowing a slight graduation of the light, revealing the depth and the visual quality of the material itself.

More than a visual effect, the pattern also allows the material to bend more easily and create the lamp shade, moving from a 2D sheet to a 3D volume. The shade and components exist as a digital file, downloadable to be made locally on a CNC router. This allows the design to be editable : the length can vary, and adding some striped parts will allow to create a customisable shape, from a triangle to a polygon. The inside and outside components of the lamp are assembled with zip ties, avoiding any glue or nails. The lamp can be hooked anywhere in the house, as a portable companion or it can stand on its own.

By using waste material and open manufacturing processes, this lamps aims to change the perception of recycled plastics, as valuable and sustainable materials to be integrated into our home and domestic environments.”