Blog

How to create an open source community around 3D printing with ceramics

The combination of ancient ceramic working techniques and digital manufacturing tools has given rise to a fascinating evolution: 3D printing with ceramics. These technologies have advanced enormously thanks to open source communities, fab labs and maker spaces, where people share knowledge openly with the common aim of fostering innovative ideas. The Jetclay project is an emblematic example of that, an idea that arose in fab labs, and that in the last years has spread to several countries around the world, becoming a sustainable company based on open source principles. Last November, Jetclay held a Jetclay Academy workshop aimed at creative profiles, funded by Distributed Design, where artists, creatives and artisans learned how to use a new small-format, open source and low-cost Jetclay printer which has just been launched on the market.

Bridging Tradition and cutting edge technology

The first examples of the use of ceramics date back to the Neolithic, so humanity has spent thousands of years shaping this material and accumulating techniques to work with it. Digital manufacturing technologies, and specifically 3D printing, has opened the door to rethinking the use of this material, expanding its uses and potential to other creative and industrial areas.

Jetclay evolution, from a Fab Lab to the Market

Jetclay was born as a project in 2017, although the seed arose two years earlier, when the architect Japi Contonente, discovered the potential of 3D printers within Maker Faire Madrid, thanks to the machines created by Gianluca Pugliese. From there, and together with his partner Alejandro Sáenz de Miera, they started to investigate the world of ceramic 3D printing within the open source field. “We knew from the beginning that we wanted to create an open source machine because everything we had learned up to that point was thanks to shared knowledge in fab labs and maker spaces, not in private universities,” explains Japi.

In 2018, in collaboration with Espacio Open, Jetclay obtained funding through the European Horizon 2020 Openmaker program, a project aimed at helping innovative initiatives in the manufacturing sector to develop sustainable business models, under the Open Manufacturing paradigm. Thanks to this funding, Jetclay was able to manufacture a dry clay extruder for ceramic 3D printing, the main milestone to develop its own business model based on open source machinery, advisory services, workshops, products and projects related to industrial design, architecture, product design and sculpture.

In 2021 came the next milestone of the project, the one that helped the Jetclay team internationalise the platform. In collaboration with Espacio Open, and promoted through the Distributed Design program, Jetclay launched the 3D Printing Bootcamp workshop. In this intensive 15-day workshop, artists from different parts of the world worked together to build a large format Jetclay printer. From there, the Jetclay platform expanded to a new node in Bilbao and in Mexico, and later on also in Germany, through the Symbiotic Spaces project, winner of New European Bauhaus 2022, and Hungary. It was also the origin of a new business project based on open source ceramic designing and printing, Godot Studio, which today carries out its activity in the Old Artiach Cookie Factory, in close collaboration with Fab Lab Bilbao and Espacio Open.

Jetclay Academy: Expanding knowledge to new profiles

As part of its business model and following the open knowledge principles, Jetclay organises workshops to extend the use of 3D printing technologies among non-technological profiles. These workshops have a double aim: learning how to build and use the machines, but also supporting participants in the development of their projects. “It is not just a technological workshop, we build the machine with the participants, mainly artists and designers, but we also help them develop their business ideas based on these technologies,” says the founder of Jetclay, Japi Contonente, “it is not just about democratising technology, but also making it more accessible in terms of use.”

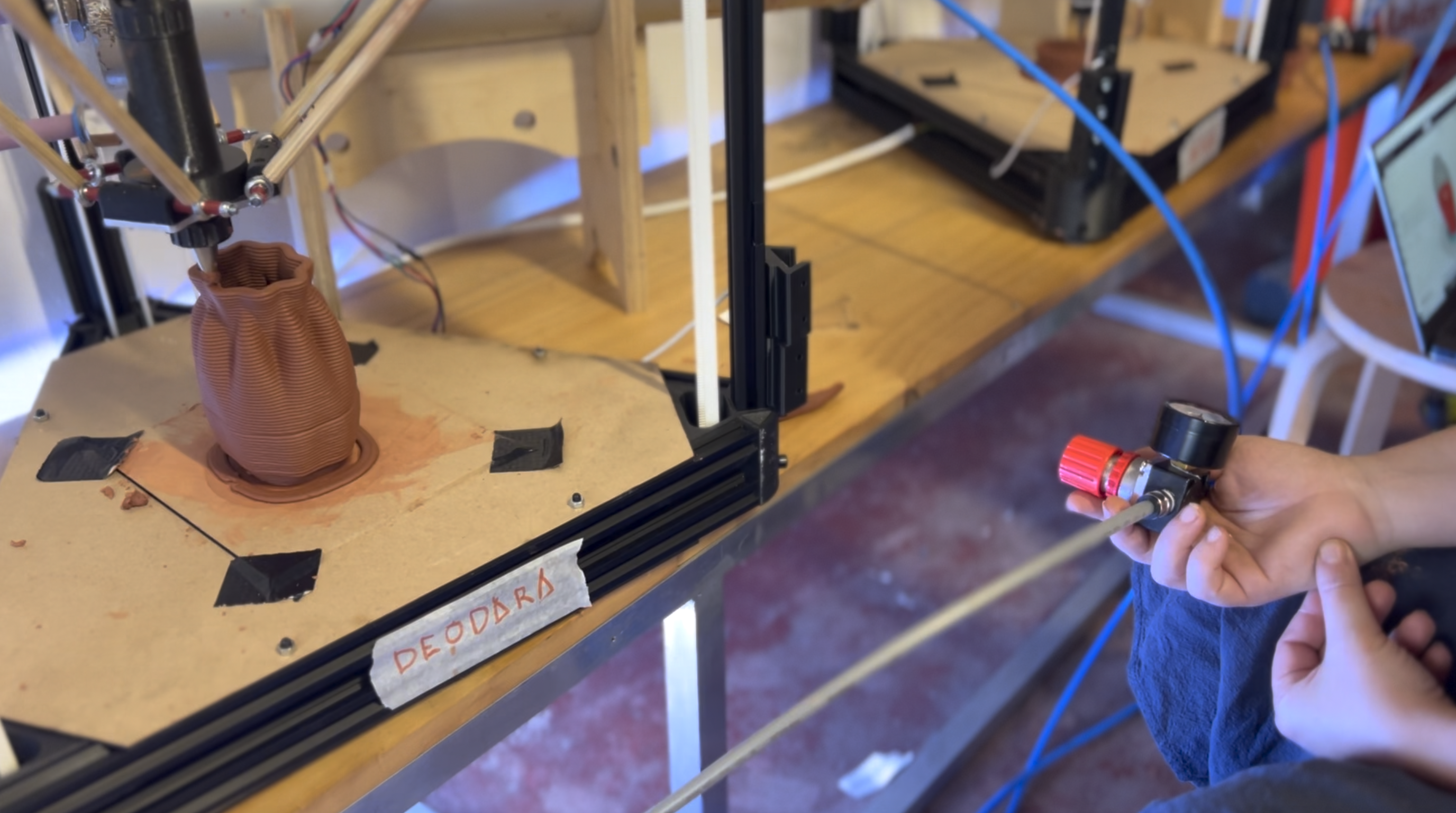

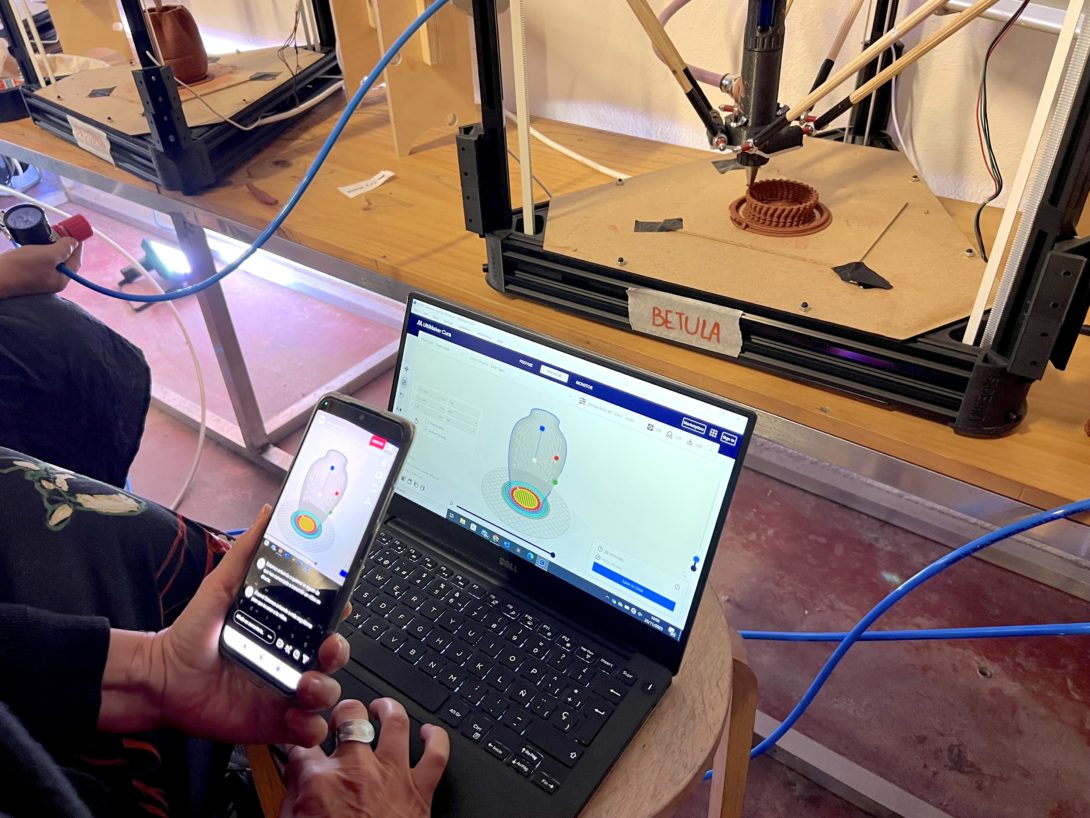

Last November, Fab Lab Bilbao and Jetclay promoted a new workshop to learn how to use ceramic 3D printers. The workshop, organised within the framework of the Distributed Design Platform, was developed within the Maker Faire Bilbao 2023 program, the International Festival of Creative Technologies organised annually by Espacio Open. The workshop was focused on learning how to use a model recently launched by the Jetclay team, a small-format, low-price printer, designed to make access to 3D printing with ceramics even easier.

The participants, who came from the fields of ceramic crafts, fine arts, academia and design, learned the basics of manufacturing and using these machines to develop their own projects. “With the workshop you don’t acquire all the knowledge to make a printer, but you do get a glimpse of what is behind the black box,” explains Japi, “the Jetclay community continues to grow so if you have any problem you can always ask and someone who has faced the same problem will help you solve it”. That’s the magical engine of open source that continues to push innovation further.

The creative professionals that participated in the workshop were:

Riley Cook

Artist focused on drawing and painting. Her project involves the close ties between human impulse, intense emotional states, organics, and memory. The project attempts to express the irrational and confusing nature of human perception, and her hope is to achieve a sense of equilibrium, homeostasis, stability, and comfort despite the assymetry of the forms. I want to create intrigue in the viewer that they are rewarded with new ideas, impressions, and hopefully inspiration upon each viewing. She has experience working with clay and other materiales to create sculptures and wishes to add the 3D printing techniques in her creations.

Saray Pe?rez Castilla

The ‘The Desert We Are’ project is made up of three-dimensional palimpsests that fuse Murano glass, 3D ceramic printing and interactive technologies to address desertification in the European rural landscape. Aimed at scientists, environmentalists, local communities and lovers of contemporary art, it uses collaborative processes and traditional materials to question the perception of the territory and reflect on the exploitation of the land. In collaboration with Jetclay and Godot Studio, and within the framework of this project, Saray Pérez has developed a series of 3D printed ceramic columns based on the scanning of remains of materials that the sea returns to the beaches. This project seeks to represent the souls abandoned in the Mediterranean Sea in their journey to reach Europe.

Nuria Pozas Corredera

In her studio located in Avilés, she is dedicated to creating dishes, tableware and special pieces for chefs and professionals in the gastronomic world, using artisanal techniques. Her intention is to include 3D ceramic printing in her creations and implement augmented reality to create a unique and different experience for the companies and people who use her products.

Javier Enri?quez Pereda

He works as a teacher at the Cantabria School of Arts, developing jewelry projects with students. Three-dimensional design, digital manufacturing and experimentation with new materials are the core of the subject he currently teaches. From public school he understands the teaching of design as a value for people and their environment, while transmitting to students the power of design to promote transformations in society and improve people’s lives.

Eula?lia Naveira Torres

The project ‘Impotsible Ceramics’ focuses on exclusive handmade ceramics for plants, made with traditional materials. It has a B2B approach for sectors such as interior design, architecture and culture, and B2C focus for people who love art and design. The aim of Eulalia Naveira and her partner Georgina Konstantakopoulou is to establish a new production and distribution model that enables the availability of designs for people and businesses. This new approach will not only allow a smaller ecological footprint, but also a significant reduction in manufacturing costs.

Luis Fernandez Tardido

Workshop teacher at the IED Madrid Fab Lab for 10 years, with extensive experience in FDM and SLA 3D printing. His project, still under construction, consists of the building of a modular system to create vertical gardens, using ceramic printing. The design is 100 x 100 digital open source, adaptable to different scenarios and territories. The project arises from current needs in terms of sustainability, finite resources and more resilient ways of living.

Sara Ojanguren Mene?ndez

Architect with a studio located in Oviedo, with a professional career focused on both architecture and digital fabrication, scenography and interactive interventions. She is currently developing an artistic project in the field of generative art, which investigates the limit of error and imprecision.

Leticia Orue Dominguez

Entrepreneur dedicated to the world of plants, with an online store and physical store in the Old Quarter of Bilbao. Through her project, she collaborates with sustainable brands such as Elho and Branca de Navaes, with powerful design and ecological awareness. Her intention is to explore 3D ceramic printing to create a new brand of KM0 ceramic pieces for “mass” consumption.

Carla Alcala? Badias

‘Reduir la materia’ is a research project that proposes the recovery of black ceramics as an environmental strategy. It is a long-term research developed as a doctoral thesis proposal that includes the exploration of ceramic 3D printing as a manufacturing method. One of the main objectives of the project is to be distributable. To do this, a series of 3D models will be designed that can be downloaded through digital platforms.

Pia Pinedo

Her project focuses on making an Udu (musical instrument) with 3D printed ceramics. The Udus are manufactured manually with ceramics, and her intention is to manufacture a 3D model to make models of this musical instrument openly available in creative centers with this type of equipment. Her objective is to make a contribution to the musical and exploratory artistic field, and also to re-define construction methods of some instruments with new technologies, in order to give them a new evolution.