Since the beginning of the Covid-19 crisis that we are experiencing on a global scale, communities of makers got mobilized to respond quickly to the needs of healthcare staff. This was made possible thanks the culture collaborative work, cnc machines and open and shared knowledge.

Around Paris, the members of the Fab City Store network were part of the movement, individually or as part of an initiative, and adapted their activities to either respond to the emergency by sharing their expertise and participating via the makerscovid.paris collective, or continue to produce content and experiment with their community.

A territorial collaboration

In these exceptional circumstances, everyone wanted to contribute to the implementation of a distributed manufacturing network. But how to contribute, which initiative to help, what tools to put in place to collaborate, how to identify the material needs of nursing staff and exposed?

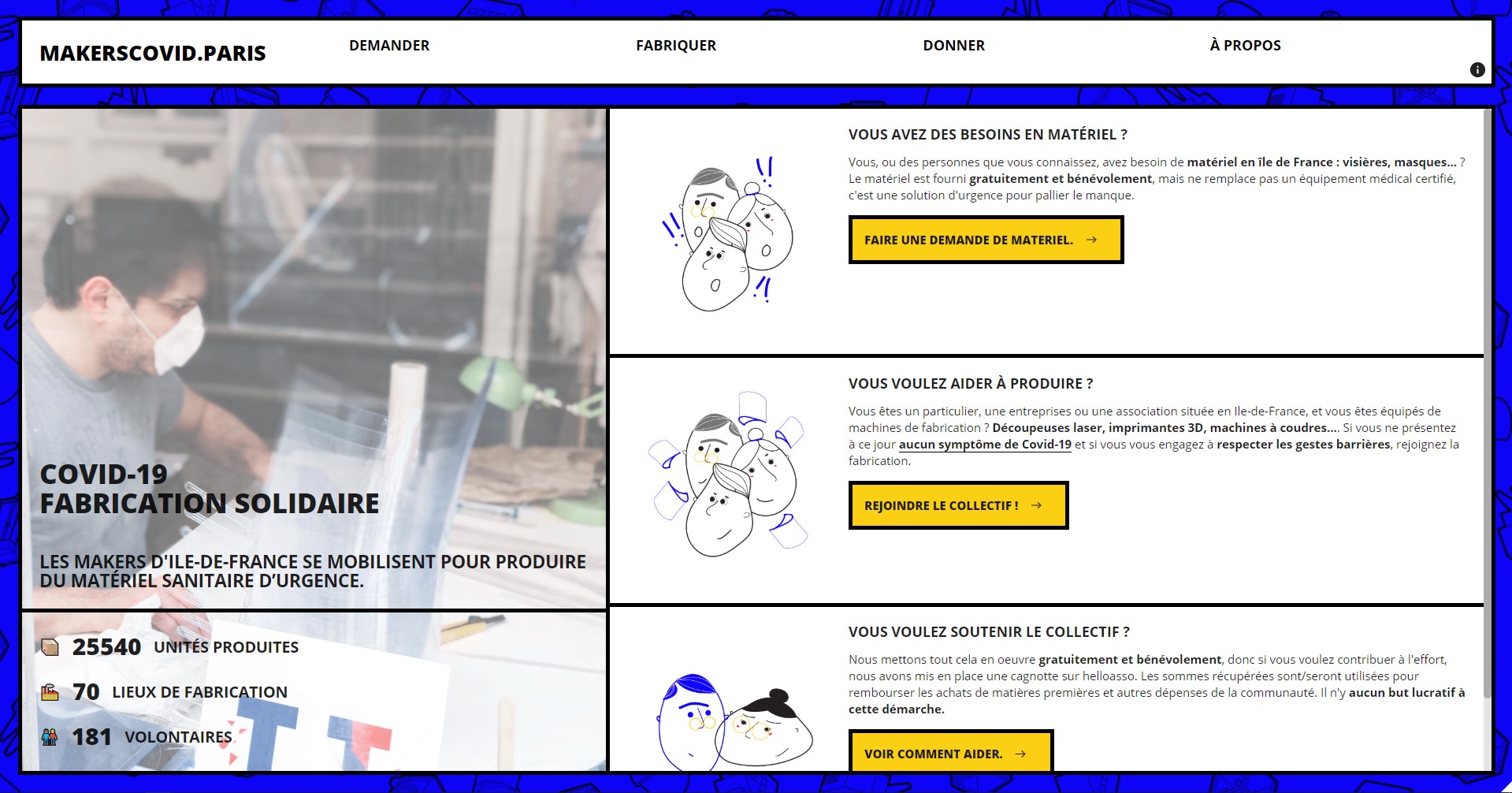

Faced with the frustration of not knowing how to contribute and without initiating an additional movement, several places and actors from among others the Fab City Store network came together to pool needs and tools within a collective: makerscovid.paris.

Quentin (WoMa), not being in Paris at the time, was able to focus on organizational and logistical questions: “At the beginning, it was quite simple and basic, with an online spreadsheet we collaborated with the group of close actors that we already formed: Volumes, Woma and Ars Longa. Then, L’Atelier des Amis, Mon Atelier en Ville and SimplonLab, which were the first labs involved in the fabrication, transmitted part of their operation to the common spreadsheet. Finally, with the increasing demands of the City of Paris and the Salvation Army, we quickly found ourselves being around twenty factories to respond to demands and coordinate our actions. “

To support and facilitate this global mobilization, the organization was very informal at the start: phone calls, facebook and whatsapp messages … We then gradually structured ourselves: “Indeed, we quickly realized that it is necessary to set up a website where the information can be updated almost in real time and where the volunteers will have all the information to join makerscovid.paris. ”

At Ars Longa, the members were unable to access the labs and quickly decided to focus on the communication elements to share the actions of the makers. Different communication elements are put in place but they are not sufficient. Thibaut, Soumaya (Ars Longa) and Quentin (Woma) met on Figma to “homogenize the visual elements already created and to create a visual identity.”

Iterative dynamics and manufacturing protocols

Since the beginning of the movement, a great diversity of different models of open-source visors, coming from the hyper-active 3D printer community on facebook, discord and other networks, have appeared, each adapted to the local feedbacks obtained.

Yoann, fab-manager at WoMa, started prototyping 3D visors at home and then in the fablab. He returns to the fact of continuously iterating on the open source models: “It is a work of experimentation, of adaptation of files to our machines but also to the materials that we have available, continuously ! At WoMa, we started production with two 3D printers, and currently have 9 printers and a laser cutter. We started using it when a resident of Volumes developed a laser cut visor model. ”

This model that Yoann talks about is the one developed by Aruna, from the Unwasted studio within Volumes. The visor is optimized to limit leftovers and allows you to work from standard elements. For a month now, this free model has been distributed within certain labs, regional and national, and allows these anti-splash protections to be produced at a faster pace.

For Yoann, this involvement in a solidarity movement is “a rather unique experience because it was necessary, in a short time, to set up a“ production line ”which could not only be effective but also be used by other people , who do not necessarily have in-depth knowledge of the topic. It means documenting the process, using the machines and using communication channels to interact with the volunteers. ”

Implementing this distributed manufacturing within fablabs and other makerspaces requires certain adaptations that was made possible by the agility of the people and tools. “It also requires being rigorous on the proper use of space (storage, cleaning, disinfection) while keeping other users informed of progress (production, stock, problems encountered, future supplies …). We had already worked on guides for autonomous users, but these were rather generic and basic. It was necessary for these sanitary circumstances to establish rules for the use, in order to guarantee everyone’s safety and the efficiency of the work we do there. ”

Managing space and production is too much of a workload for a single person. So it was also a question of delegating responsibility: “From a certain time, we managed to mobilize a few people to be in charge several days a week. But, having set up production and being the main referent, I remain available all the time to solve problems encountered by the volunteers on site and manage more global problems remotely (new needs, new files that I can do at my home, supply management…). ”

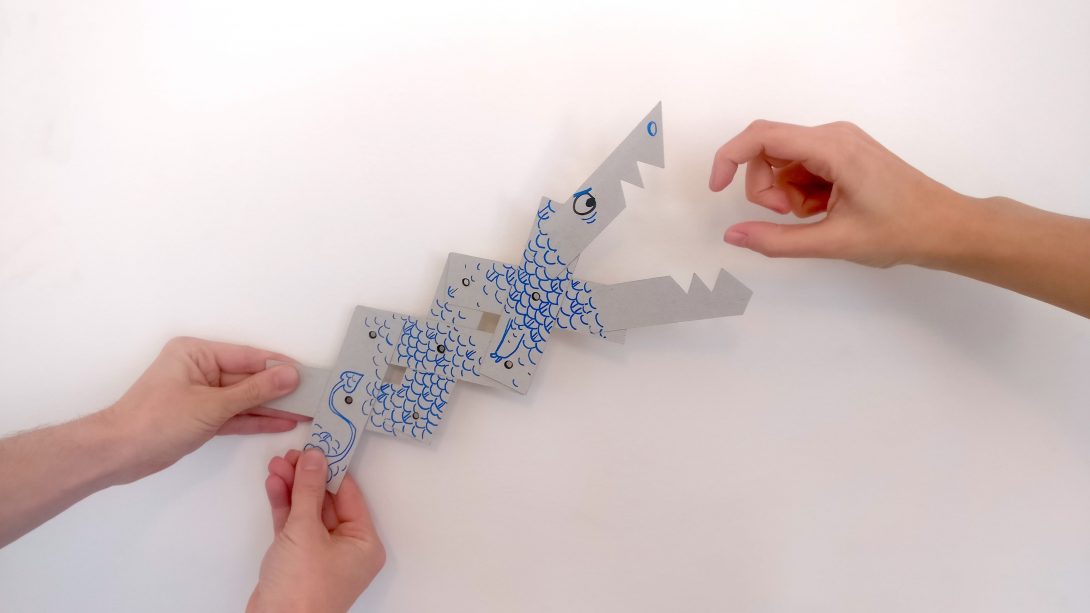

But how can regular citizens be more widely involved in this distributed and united manufacturing action ? Outside the fablabs, many volunteers were ready to lend a hand to the movement as well. Vincent, from Ars Longa and Fab City Grand Paris, developed the dynamic factory@home within the collective: “everyone at home can participate up to 3 or 12 hours by receiving kits of visors and mounting them for later distribution. Each location is capable of producing visor kits at the start of the week (pre-cut plates, rubber bands, etc.) which are distributed to the 40 volunteers at home. Once the kits are assembled and packaged, they are delivered to the fablabs which serve as distribution points for the protections ”

This re-questions the position of third places, which in addition to being productive, cat as relays for citizen-makers who print and assemble from their homes ! A network of places and actors that constitutes a distributed manufacturing network at the scale of a district, the city or the metropolis.

Sharing knowledge towards collaborative and volunteer initiatives

In her 18m² Paris apartment , which usually overlooks a noisy square, with its metro entrance, cafes, cinema … Hélène, the creator of Povera Slowdesign project, appreciates the calm. Of course, as a designer, she worries about the future of her brand: “This is the case for many entrepreneurs, it is quite regrettable and I hope that the beautiful social projects that I know will be able to continue! ” She herself volunteers her own craft to fabricate and sew textile masks for working staff with an initiative supported by La Tête dans les Nuages.

Faced with the lack of raw material, Hélène even made rubber bands from recycled tights. Inspired by her designer practice, where “she sublimates materials deemed ready to be thrown away” by relying on the recycling of pantyhose in jewelry, Hélène developed elastics with the same technique to counter the shortage in commerce.

On her side, Marie, designer and illustrator of Maa Design, uses this time of lockdown to join the makerscovid.paris collective, when Villette Makerz got into the loop: “At the fablab, it is the laser that works, we mainly produce protective visors. Things were quickly organised, Damien – resident of Fablab – manages orders (requests, deliveries), I manage the machine (production, maintenance) and we manage two (three with reinforcement) the mounting of the visors. ”

But that’s not all, Marie was also created illustrations: “to communicate about our actions, create flyers and illustrate the makerscovid.paris platform.” Combining her illustration and design skills, Marie is participating in the development of new solutions to this crisis, such as: “DIY special edition paper masks that can be found free on my site.”

Yoann, returns to his personal situation where “in a situation of technical unemployment at the Fablab de Woma, I kept an eye on what was being done across France, but also in the rest of the world, especially the countries most affected. Seeing initiatives set up on the production of visors, I ordered elastics, rhodoid sheets, and started to test on my personal 3D printer. I was able to devote myself entirely to this production because, due to the health crisis, my short-term projects relating to my activity as an independent designer were either canceled or postponed. I still had to make choices and set aside the progress of certain personal projects, considering that the production of protections was more important. In addition, this collective experience resulted in very beautiful things. ”

“Maintaining activities, but this time with the means at hand”

For some designers, the goal was also to maintain the relation with their community during this period of physical distance. This leads to challenging one’s own activities and how to engage the public online. Pauline and Anna from Kutikuti return to the flexibility of their activity which is usually “to design workshops for children, very maker and DIY oriented.”

“During this period when so many parents were at home with their children, it seemed to us more important than ever to continue to offer something to stimulate their brains ! Since the start of lockdown, we have therefore offered more than 20 workshops to continue developing our creativity, but also to discover new technical or scientific concepts. Everyone can take stock of the pieces of string, plugs and boxes that fill their house, and prepare for great experiences! ”

This approach is in line with Hélène’s feedback, who, given her “shattered schedule with what is happening outside”, could no longer carry out her workshops physically. So she set up and tested her first online workshop in early April and will be offering more soon. This agility is one of the characteristics of these entrepreneur-makers which means that whatever the situation, they are able, according to Pauline, “to maintain activities, but this time with the means at hand”.

“There is no other possible model than relocated and distributed manufacturing”

For Michael, who coordinated the various actions of makerscovid.paris on logistical and political levels with the institutions: “It is important that this cohesion and the wider cooperation continue. This question of a longer-term cooperative model is on everyone’s mind, and is also accompanied by questions about the structuring of a local manufacturing model and its economic viability. In reality, the answer that everyone has been able to demonstrate shows that there is no other model than relocated and distributed manufacturing. ” It is of course too early to have a clear vision of the future, but the experience of the past few weeks demonstrates the capacity of places, actors and creators of the network to adapt in a situation of crisis, and the real added value of relocation.

For the Fab City Store, the role of this mobilization and this ability to create new models is also to support the creators of the network who all have little visibility on the future of their activities. But also to structure this cooperation so that everyone can share and help each other to resume business. For Hélène, “the rest lies in this union. For the rest, I don’t know how to resume my activity, but I have lots of ideas! ”

Written by: Michaël Araujo, Soumaya Nader and Quentin Perchais, from Fab City Store.