wamake

Useful information

- Team members

- Birgitt Deckers Ruben Braeken

- Country

- Belgium

- Keywords

- flexible modular circular zero-waste biomaterials social economy

Short Description

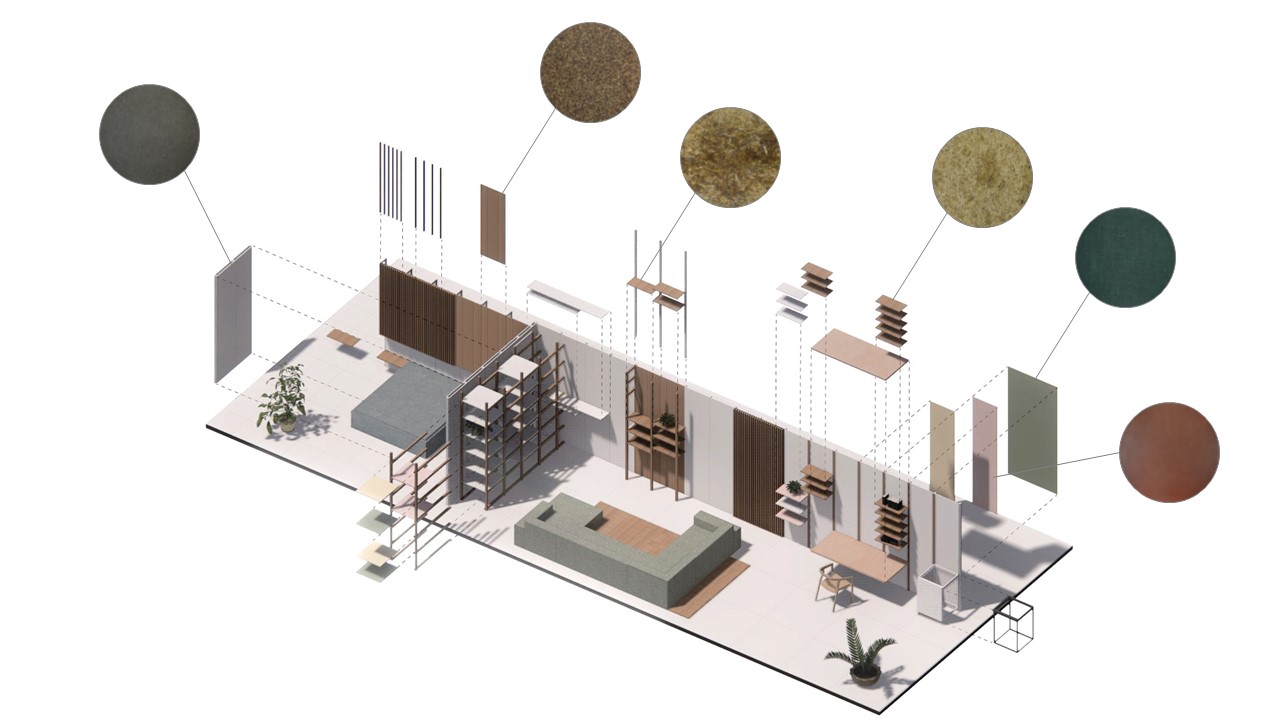

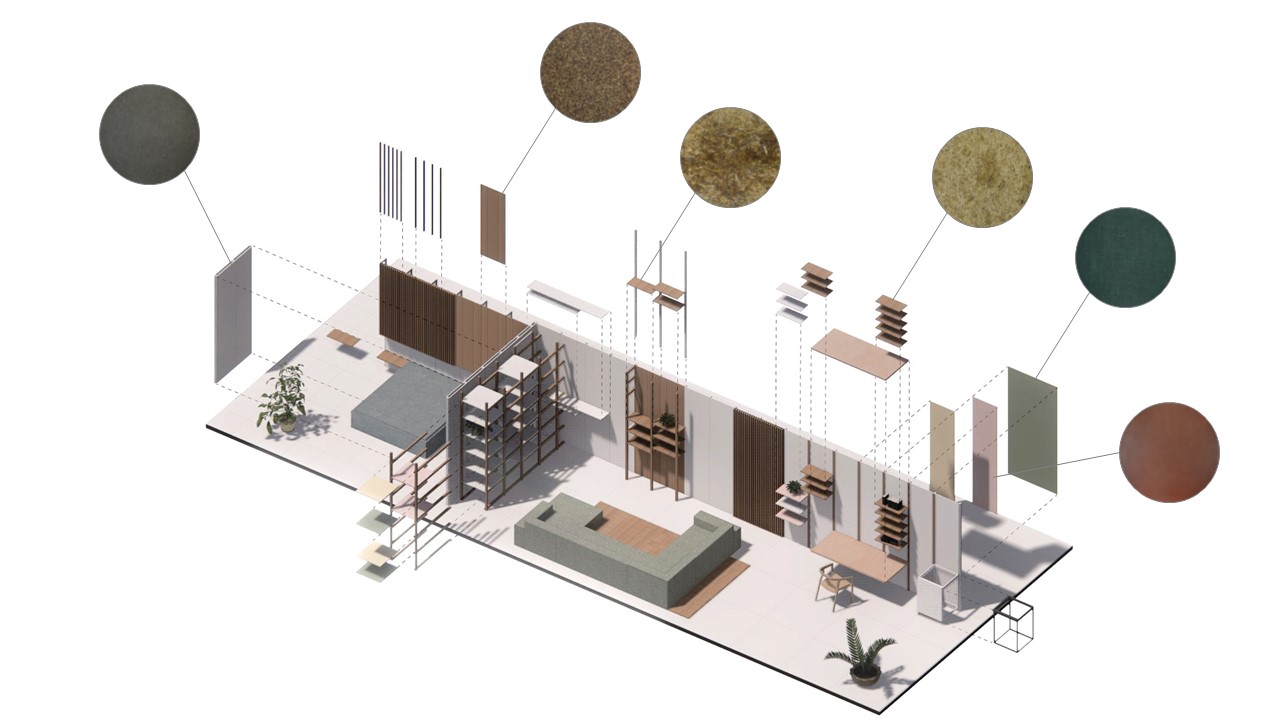

Flexible circular interior system consisting out of a metal frame finished with biobased materials

Detailed Description

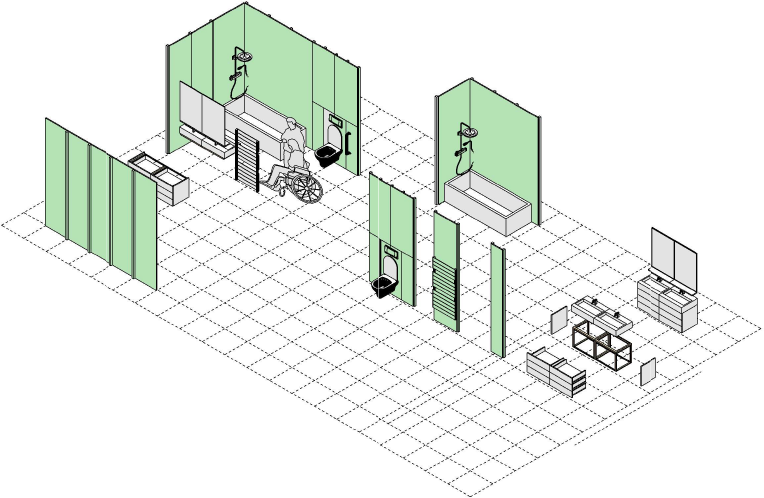

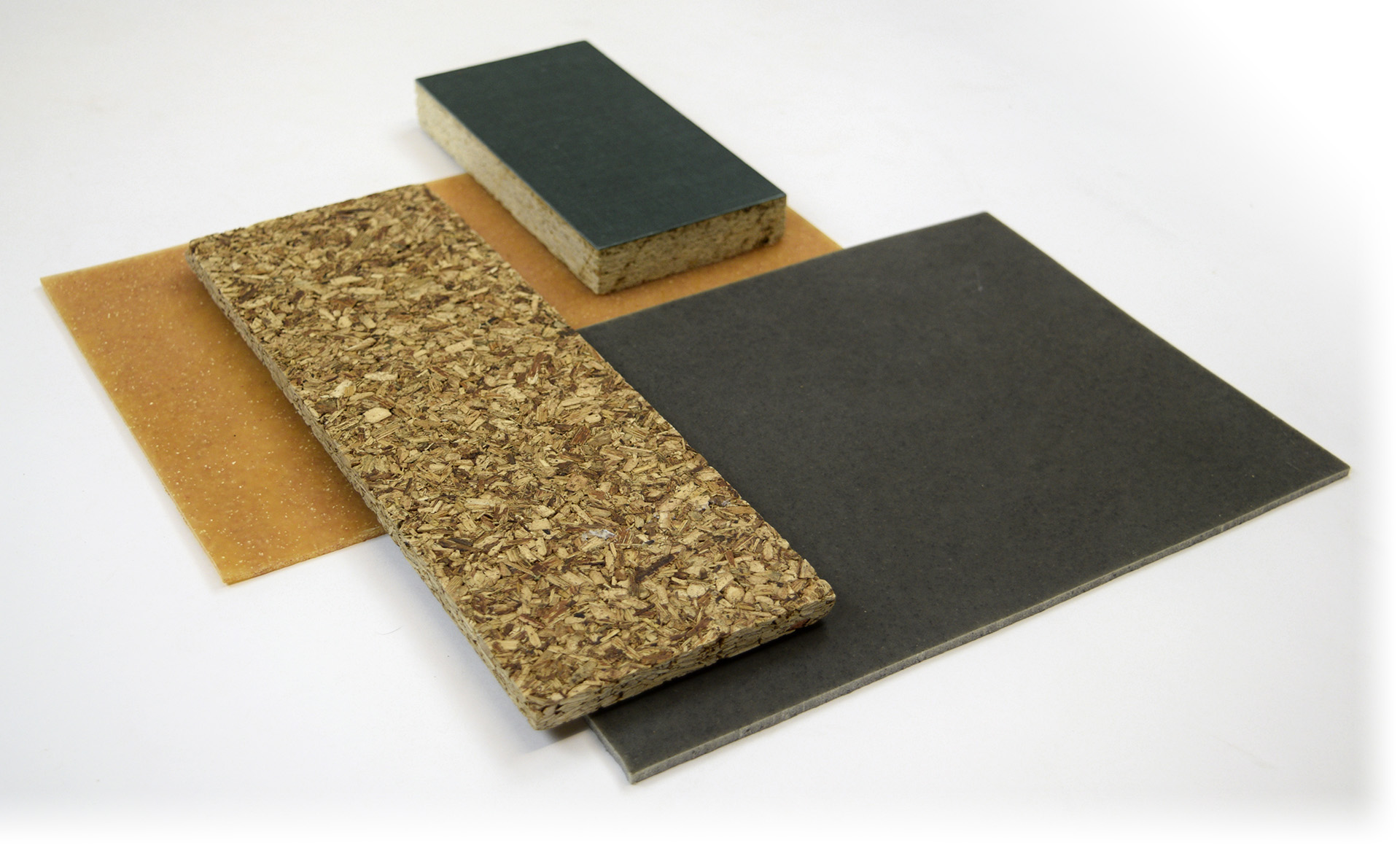

Wamake is a collab between a sustainable industrial designer and a circular architect. Together we want to change the way people use their spaces and the products in it. We've created a flexible system which you can rebuild endlessly to your needs. You can build cabinets, wall finishings, partition walls, furniture, and even an entire kitchen or bathroom.The metal frame is durable and with our smart connections it's childsplay to change the configuration and the look. The panels for finishing are made out of local waste streams, e.g. tomato plant fibers or textile waste with 100% biobased binders, currently made in Belgium. We educate long-term unemployed and disabled people to assemble and install our products at customers (office spaces, retail, hotels, events and private) . Every year over 10M tons of furniture goes to waste in Europe alone. Wamake offers a service to take back the panels to repair, composte or recycle them into new ones. No more waste in the furniture industry.

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

By involving otherwise unemployed people in our production process. We strongly believe that social economy plays an important role in making the circular economy work. Therefore we offer training programs for making the panels, order picking and installation at customers. Moreover, our panels are formaldehyde and plastic free so interiors built with wamake are healthier to live in.

- Does your design support sustainable production, embodying circular or regenerative design practices?

Of course! Currently our solution is 100% made in Belgium. We work with a local manufacturer for the metal frame, which can be reused en rebuilt (almost) endlessly. The panels are made out of local plant-based waste streams (e.g. coffee, tomato plant, flax, cotton, cork...) together with a biobased binder. We work with 2 types of Belgian binders. One is fully biodegradable but is not (yet) suitable for use in humid conditions. The other is not biodegradable but is extremely durable and watertight. With our take-back service, we make sure the panels can go safely back to nature (in case of the first binder) or repaired, reused and in the worst case safely recycled (in case of the second binder).

- Does your design use principles of distribution and open source?

Yes! We want to avoid transport as much as possible so we only sell locally (600km radius). In the future, we will use a franchise model to scale our business. This means we will set up wamake in other regions, using the same technology but with local waste streams and makers. In addition, we will organize workshops and design competitions so anyone can create new panels. We will sell them (sometimes in limited edition) via our online platform. Customers can then use the configurator to design their own interior. Moreover, we also offer sustainable and circular products from other (local) brands. In this way, wamake is a one-stop-shop for a sustainable and healthy interior.

- Does your design promote awareness of responsible design and consumption?

Yes! First of all, the biobased panels have a natural look and will bring biophilic design into any interior. By making the system flexible and timeless, we believe customers will hold on to to the products much longer because it's so versatile. Wamake also informs customers via the online platform. Every panel will have a detailed description of what's inside, for example. Customers will get a reward when they use the take-back service in the form of a discount on new panels or metal structure. We hope in this way they will never throw wamake away.

Images