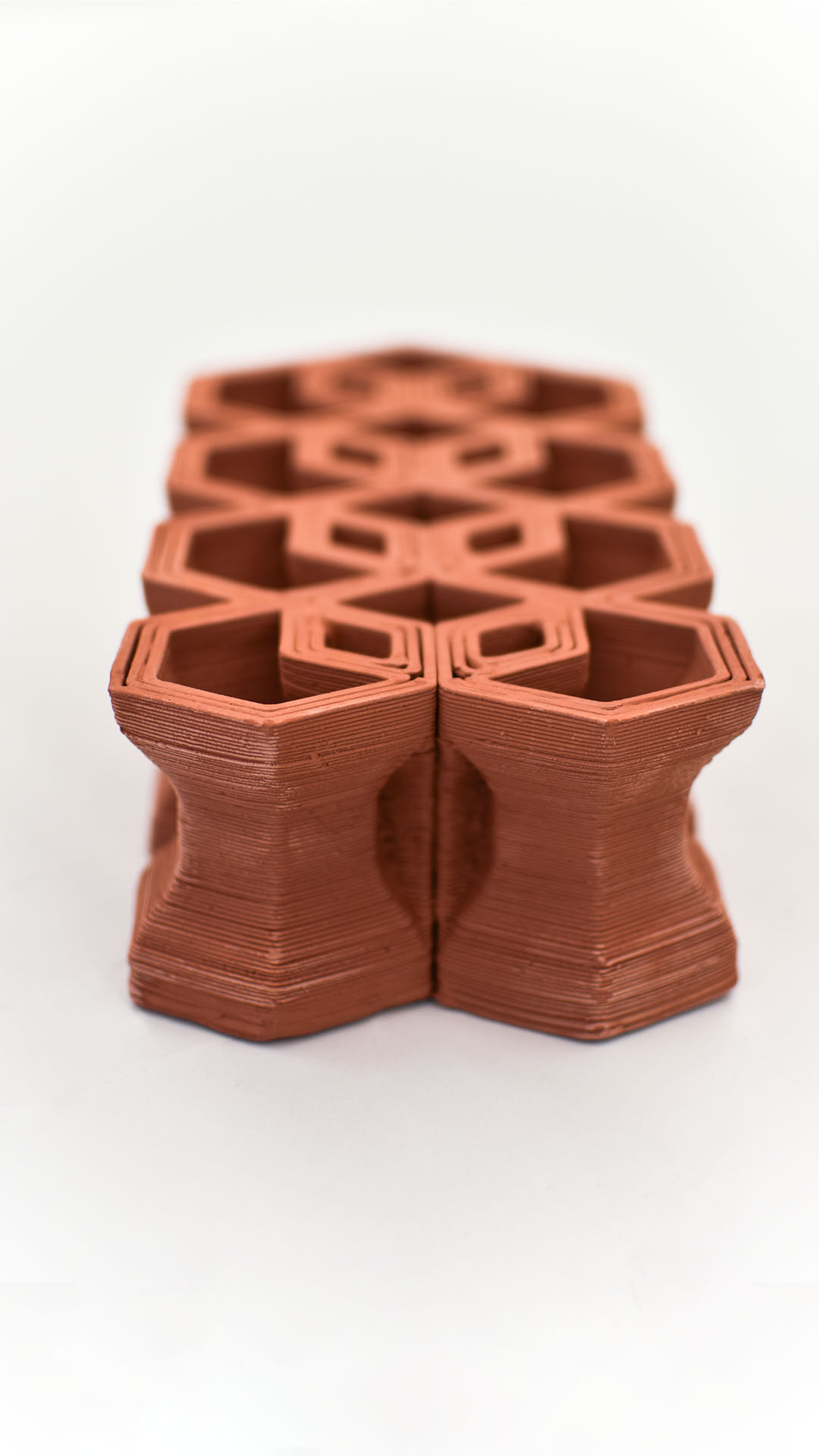

HOSE PILLAR, A 3D PRINTED CERAMIC BRICK

Useful information

- Team members

- Foteini Kolaiti

- Country

- Greece

- Keywords

- 3D printing ceramic brick architecture self sufficiency sustainable clay mimicry

Short Description

An air cooling 3D printed ceramic brick as an architectural component for sustainable housing.

Detailed Description

The project is about using clay 3D printing technology to produce a ceramic brick that could replace the use of air conditioning with high CO2 emissions in order to cool down interiors. I got inspired by the wide use of the Roman brick which encouraged building technology for centuries. I used the ratio 4:2:1 to design a 3D printed ceramic brick that corresponds to the Roman brick dimensions. The 3D printed terracotta brick promotes zero energy consumption and self sufficiency for thermal comfort in hot and dry climates. My vision is to provide a sustainable solution for heat waves by replacing high energy performance air-conditioning with cooling brick walls in a similar frequency as the Roman brick existed. The structure of the “Hose Pillar” brick obtains narrow corridors which compress the incoming air and release it cooler in the interiors, yard sites or terraces of buildings. It is a mimicry of air-conditioning while the design objective is to use no energy to lower temperature.

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

The climate change is one of the urgent motives to examine when thinking about a greener design. The increase of temperatures is affecting the needs to be covered when designing according to climate requirements. City areas together with dry climate regions are already in a crucial need of cooling down during warm periods. Dwellings that are built according to past environmental needs will no longer be functional enough to host the residents because of extreme high temperatures. In order to offer a comfortable and healthy living, new building fabrication will take under consideration the survival into the phenomenal issue of urban heat island. Future of design and architecture is meant to be green from the stage of production until the building performance and maintenance.

- Does your design support sustainable production, embodying circular or regenerative design practices?

In an attempt to increase the sustainability standards of the project I chose ceramic material for the Hose Pillar brick. Ceramic is an excellent sustainable material because it can be produced and purchased close to the construction site, it is not toxic, fireproof, it motivates zero waste manufacturing and it is recyclable. Ceramic is considered to be a low cost building material and financially sustainable with long lasting life that provides low maintenance needs. As an important architectural component it has a long chronological use during the past millenniums and even in the end of its life it can be renovated in order to enrich and highlight walls as a cladding material. It is interesting to mention that ceramic bricks have a low thermal conductivity during the warm seasons and they can offer a relief of the discomfort of the so called urban heat island caused by the dense concrete architecture of cities.

- Does your design promote awareness of responsible design and consumption?

3D printing is a modern technology which encourages zero waste production as well. Raw clay used for 3D printing is recyclable and will be always returning inside the tank of printer to be extruded into the desired form. As a manufacturing process it requires one material and one tool(the 3D printer). The 3D printed ceramic brick , as emerging object elevates the energetically autonomous housing and introduces 3D printing technology in architecture. The production results of ceramic 3D printing offer durable and airy results in the case of brick design and the final product is customized according to the color and the size depending on the customer’s needs, by keeping the same ratio.

Images