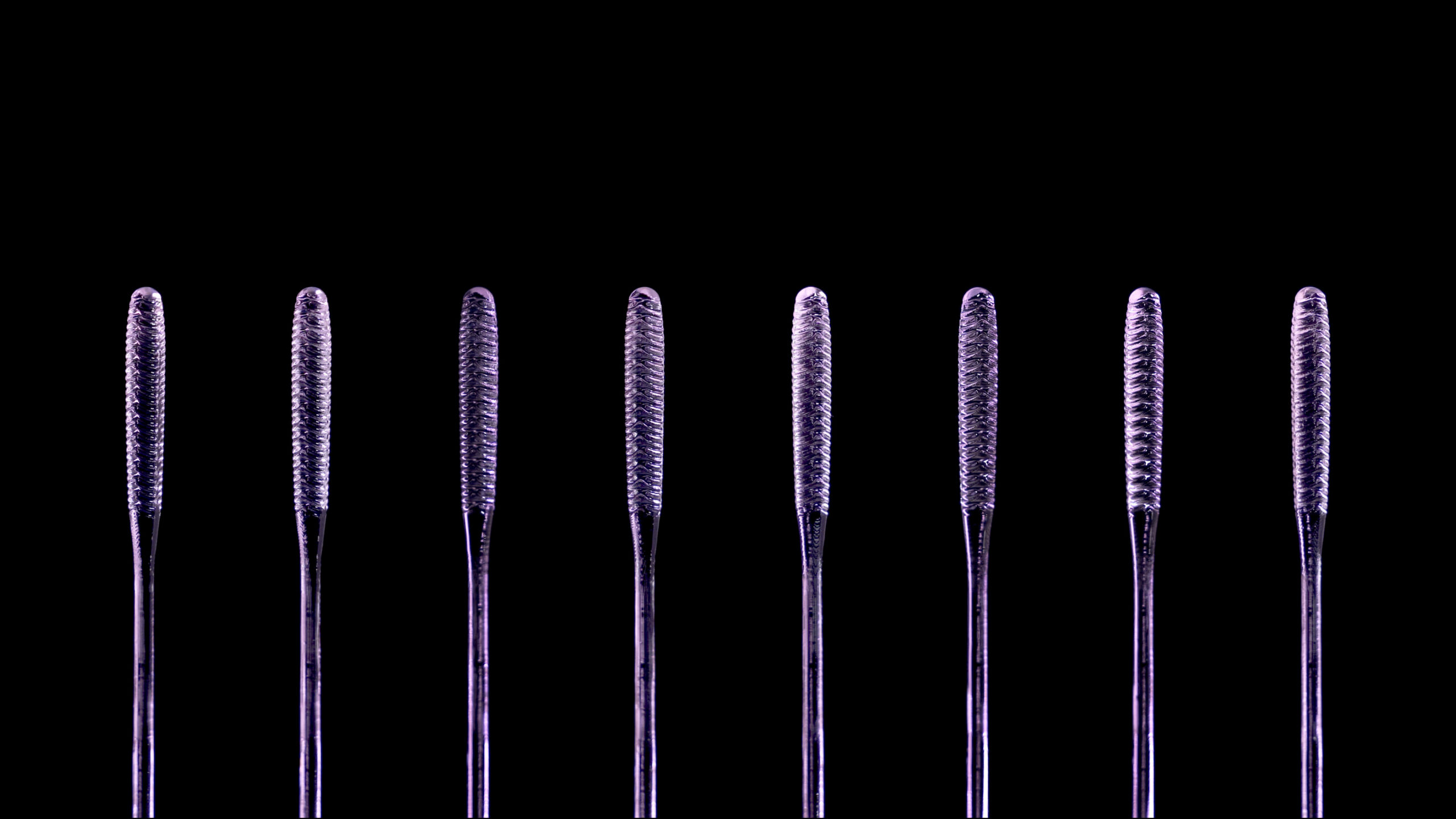

CRN_01 "Hummingbird" Swabs

Useful information

- Team members

- Maciej G?owacki

- Country

- Poland

- Keywords

- covid lab testing availability diagnostics medical rapid prototyping

Short Description

CRN_01 testing swabs simplify the production in response to covid-related shortages of supplies

Detailed Description

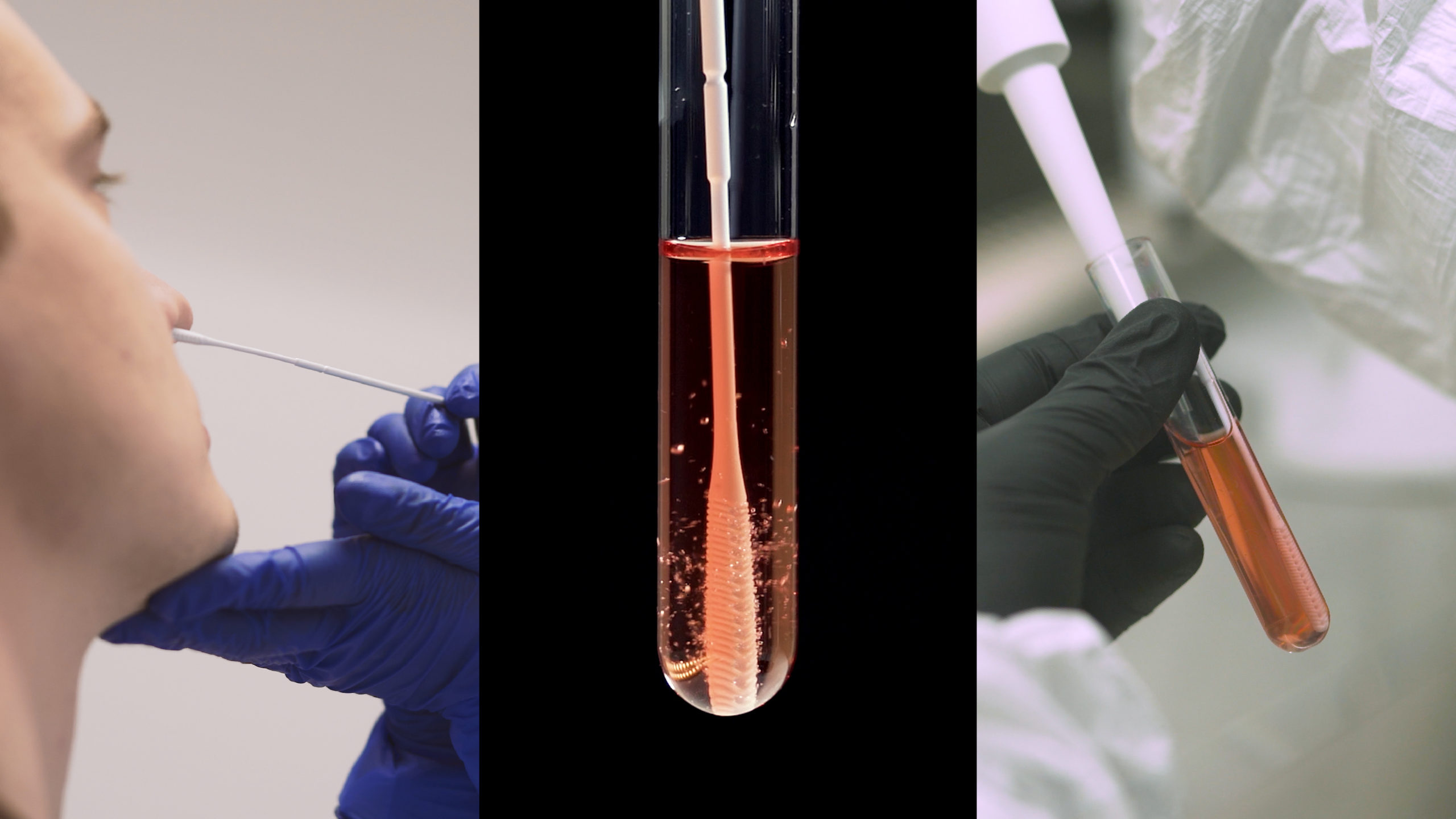

CRN_01 swabs were developed in response to shortages of medical supplies at the beginning of COVID-19 pandemic.

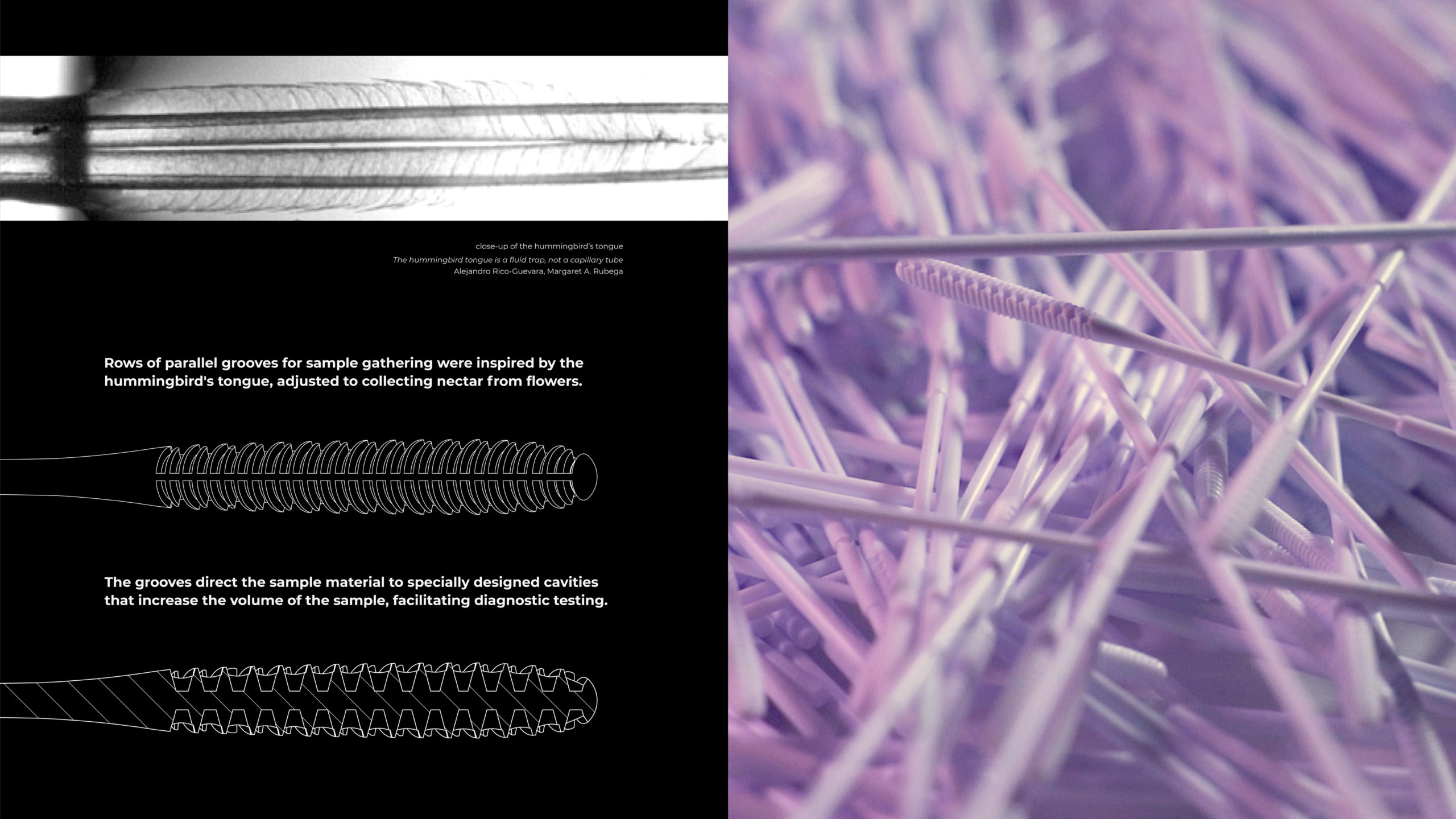

The aim was to simplify the manufacturing process of swabs and make local production much easier. Nowadays, they are manufactured in two stages: injection molded and then flocked. In order to obtain the right parameters, specific flocks are needed, and thus also proper machines for their application. The CRN_01 has a one-step production process – just the molding.

In the spirit of biomimetics, the form of the swab was inspired by the hummingbird's tongue, adjusted to collecting nectar from flowers. The designed grooves and cavities allow for collection and deposition of large amounts of sample material, thus ensuring testing efficiency. Moreover, due to the lack of flocks, CRN_01 swabs “give back” for testing more of the collected sample than regular swabs.

The project passed verification by diagnosticians and the first injection mold and production series were made.

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

During the Covid-19 pandemic the whole world learned about the development and spread of the disease from the mass testing. Swabs were therefore a necessity item, and the simplification of their production a real opportunity to support health care and thus – human well-being.

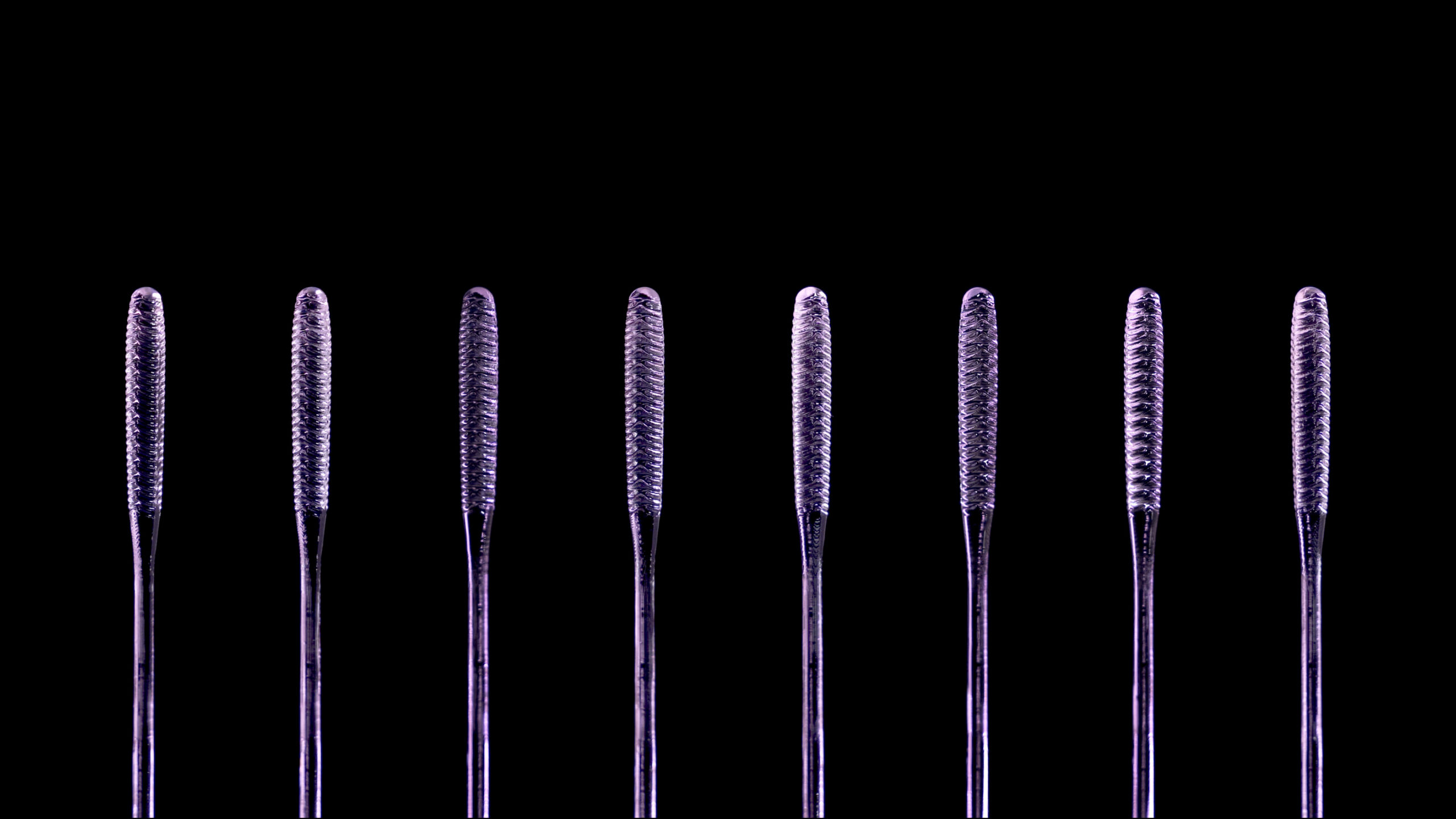

The design was optimized so that any company capable of injection molding can easily produce the swabs in times of need.

- Does your design support sustainable production, embodying circular or regenerative design practices?

As the CRN_01 swab has a one-step production process (only injection molding) and no additional flocks, its made from single material (e.g. PP). It means that it can be easily recycled and brought back into the cycle.

- Does your design use principles of distribution and open source?

The design files have not been uploaded online yet, however the project was shut down due to lack of financing and is not meant to bring profit. The case study descibes and depicts it in detail, paving the way for similar future designs that could mean a real change.

- Does your design promote awareness of responsible design and consumption?

With its aims of making production process accessible and supporting healthcare, while being in line with the circular economy, – I sure hope it does promote awareness of responsible design :)

Images