300CC | Emmanuel Hugnot

Useful information

- Team members

- Country

- —

- Keywords

- -

Detailed Description

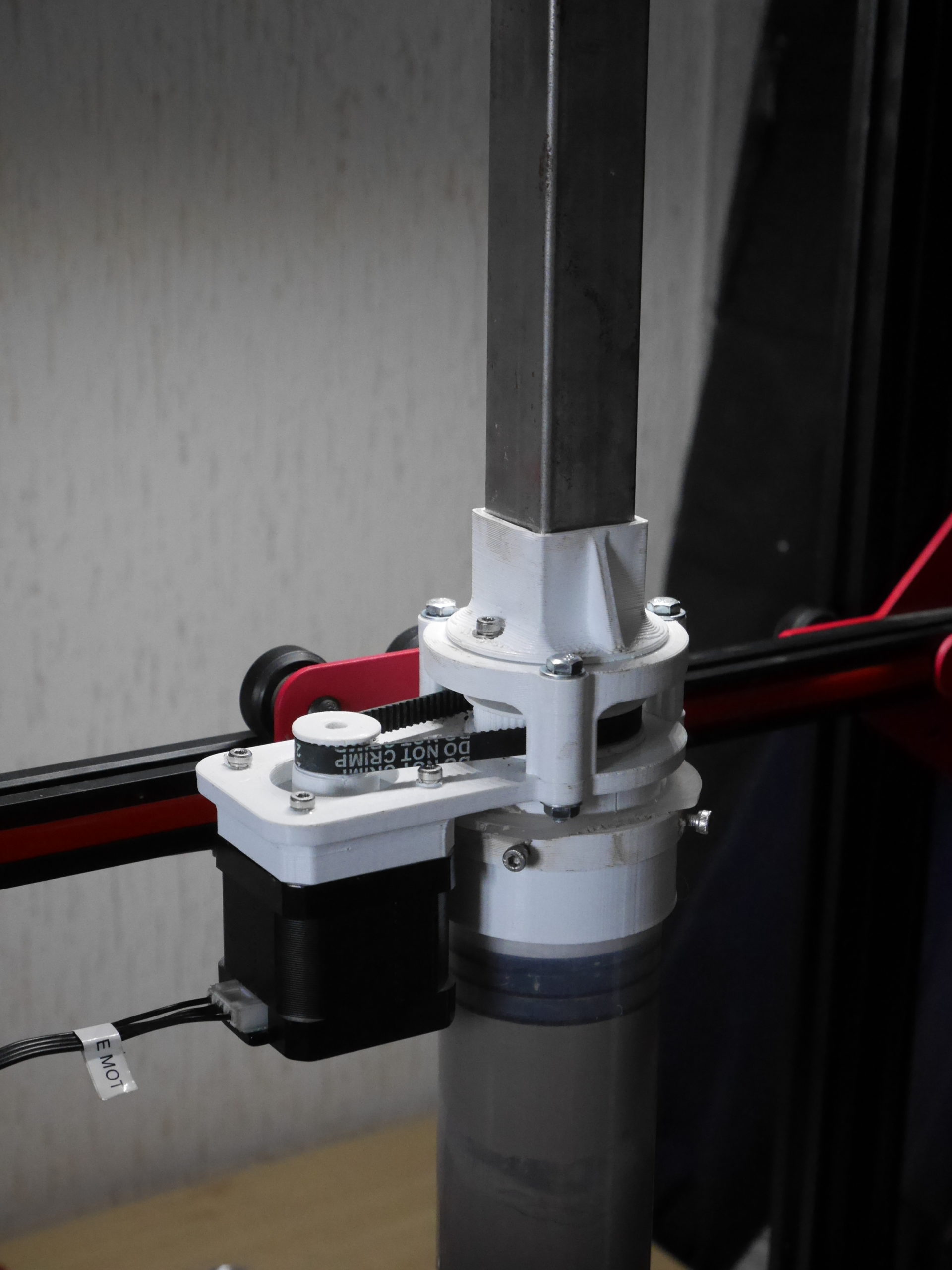

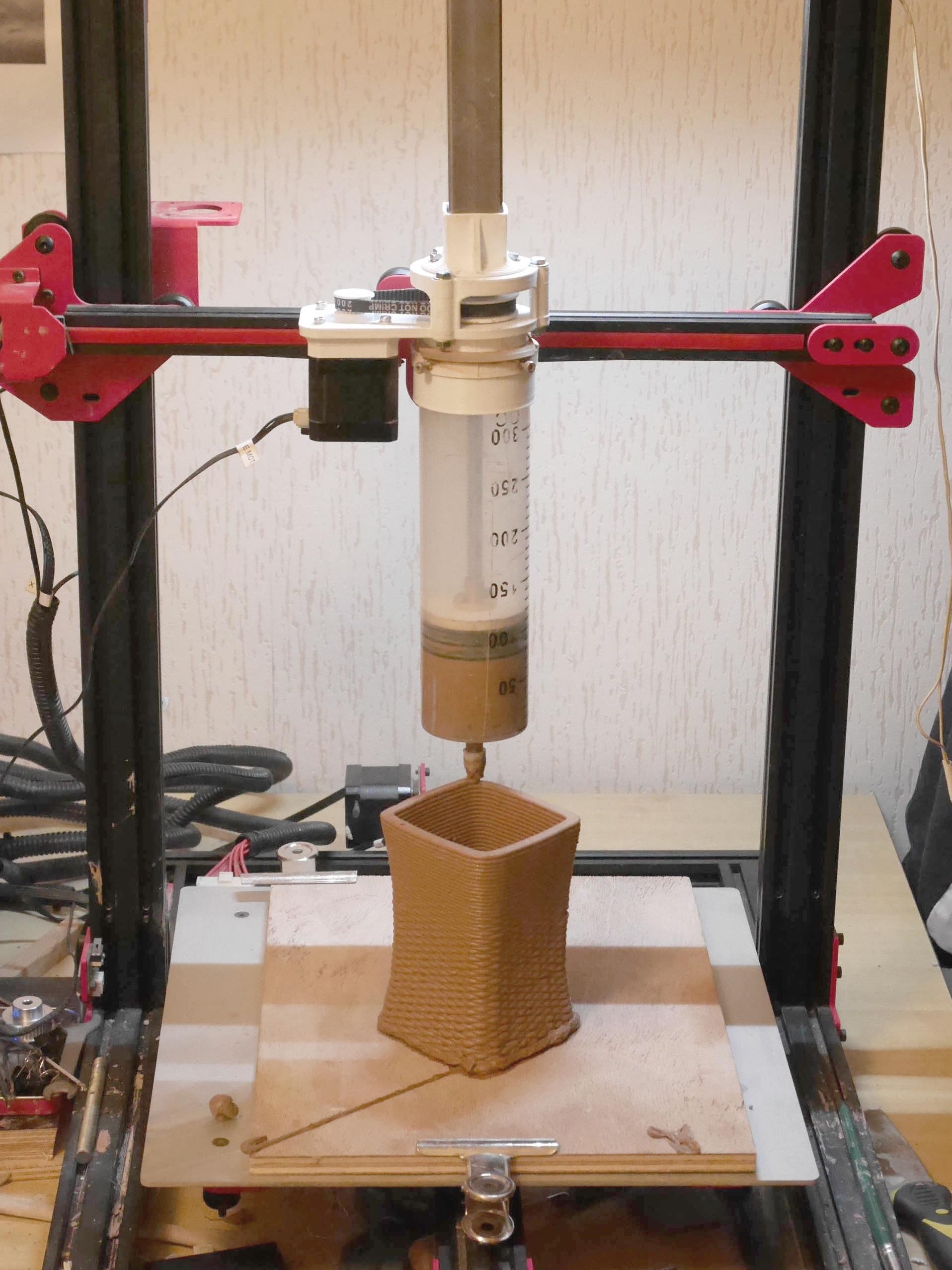

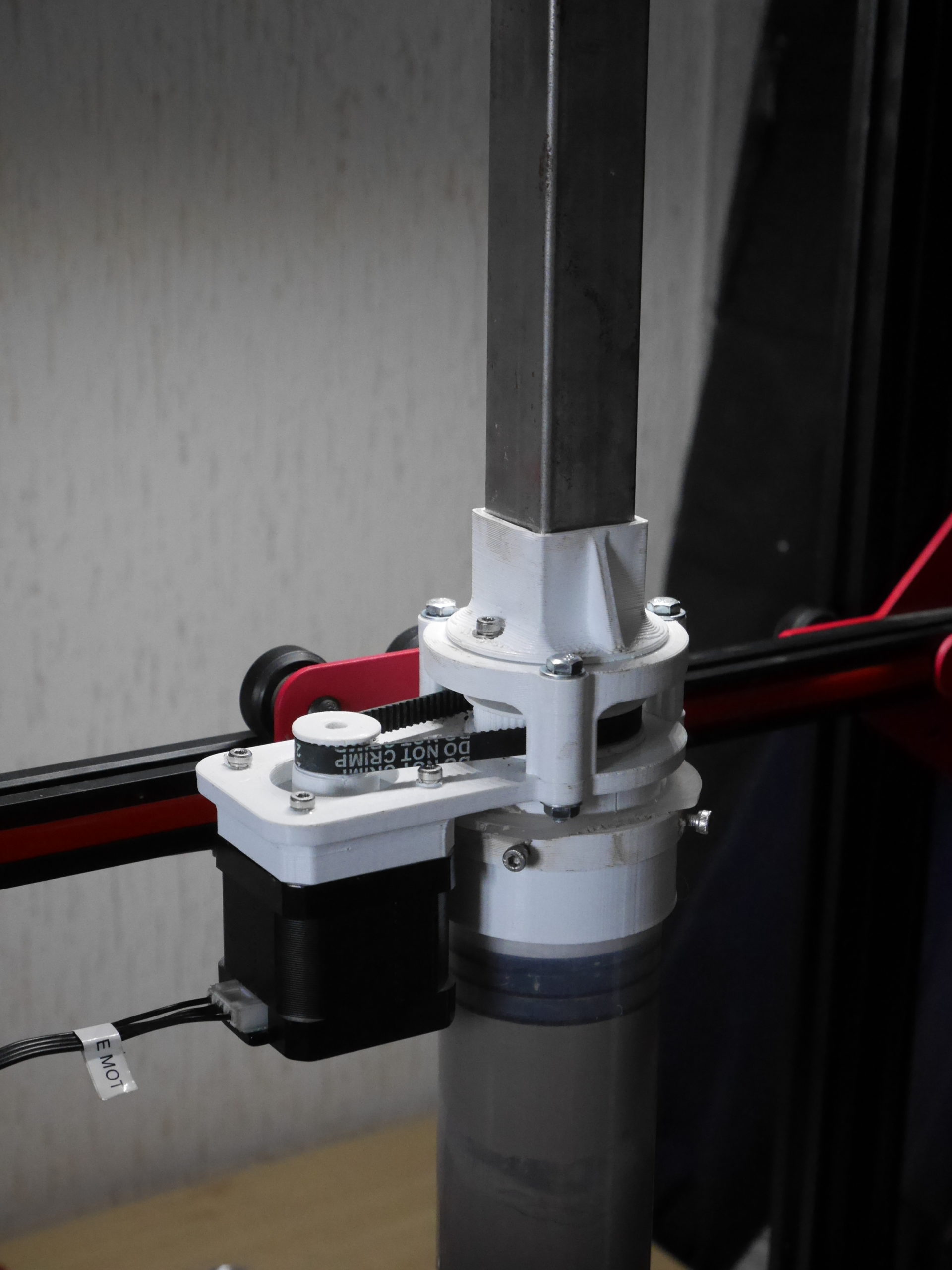

The 300CC_extruder is a mechanical extruder for the extrusion of ductile pastes. Its 300CC capacity allows to test bio-material samples or to print small quantities of clay, in spaces other than workshops. The 300CC extruder and its manual are available as open source, in an effort to encourage the development of ductile paste printing and the research that surrounds it.

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

The project is of a collaborative nature, involving improvements to the tool itself. After its Open-Source release, several people adapted it to their needs and continued to release new Open-Source plans.

Many artists/designers and makers who test the extruder give me feedback on tips and improvements, building an open community around this technique.

- Does your design support sustainable production, embodying circular or regenerative design practices?

Extruder parts are standard and can be reused. The new extruder versions that are released feature minimal improvements, allowing the parts from the first versions to be reused.

- Does your design use principles of distribution and open source?

The 300CC project is completely open and accessible. A manufacturing and assembly manual accompanies the design, and parts are standard and accessible. My instagram account and website are also important resources on the process, making every stage of my design process transparent. I'm in contact with many makers and fablabs looking to achieve similar things with my work to help and advise them. All this with the aim of accelerating open research into additive manufacturing with a focus on eco-friendly materials.

- Does your design promote awareness of responsible design and consumption?

The project can be ecosystemic in that it runs counter to the emerging paste printing industry. The cost of printing machines can be very high for young artists at the start of their careers. My project is therefore designed to enable anyone on a modest income to experiment with these techniques. The design of the extruder also allows a better understanding of how mechanical extrusion works, in the manner of Ivan Illich's conviviality, so that the user is able to understand and repair the machine himself, without being confronted with proprietary and incomprehensible parts.

Images