Hugging Suit

Useful information

- Team members

- Ruo-Xuan Wu

- Country

- Germany

- Keywords

- Hugging Suit Remote Hug Digital Intimacy Haptic Simulation Hugging Memory

Short Description

By wearing Hugging Suit, the users can remotely hug and be hugged in real-time.

Detailed Description

COVID-19 pandemic changed humans’ interactions and highlighted the demands for remote haptic communication since most restrictions relate to avoiding physical contact. For international students, having a physical hug from family became an extravagant wish, because of the high travel costs and consumption time. Hugging Suit was built to realize remote and real-time haptic communication. The user only needs to embrace the Hug Sensor, the paired user can feel the hugs by wearing the Hugging Suit.

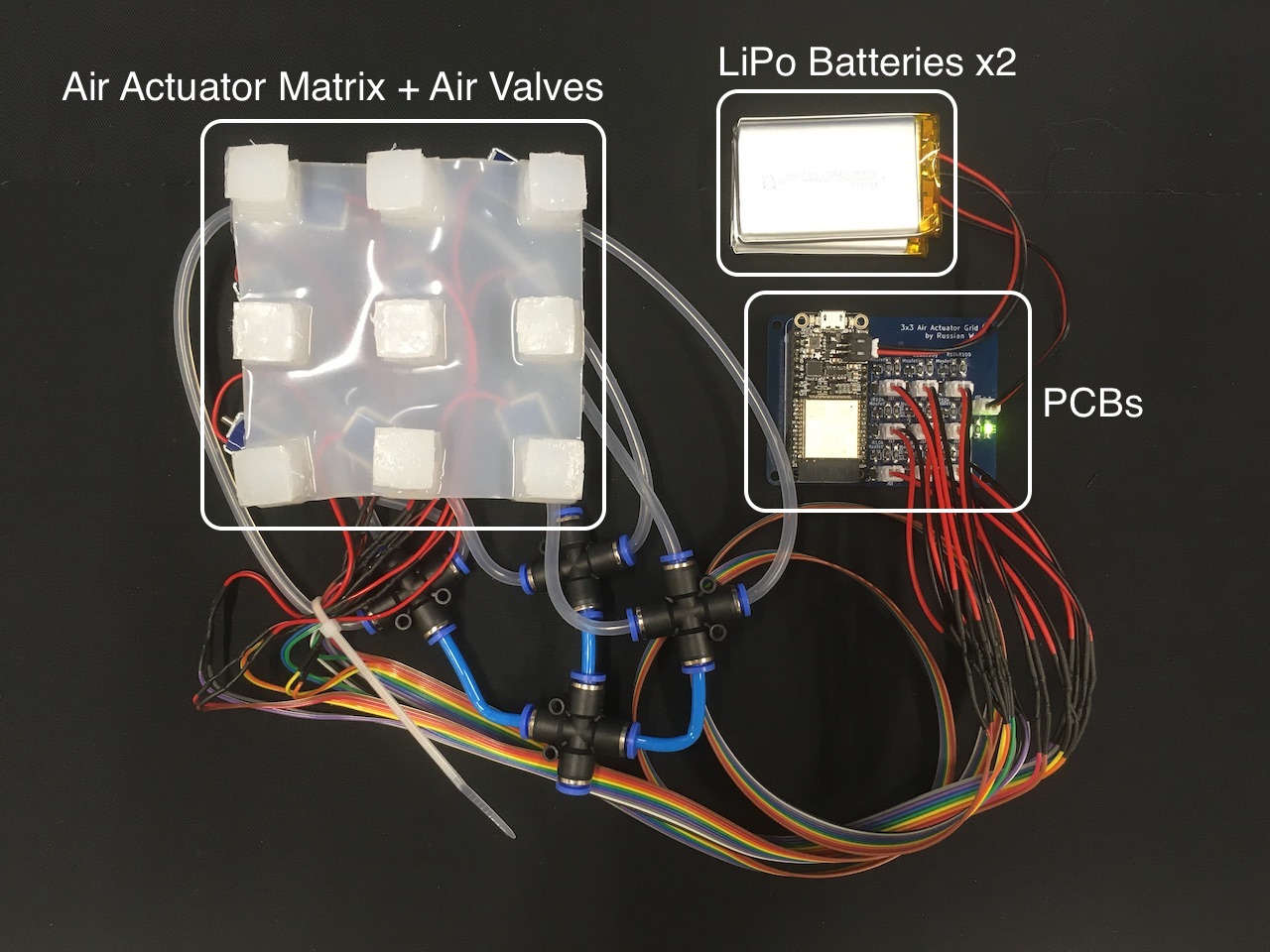

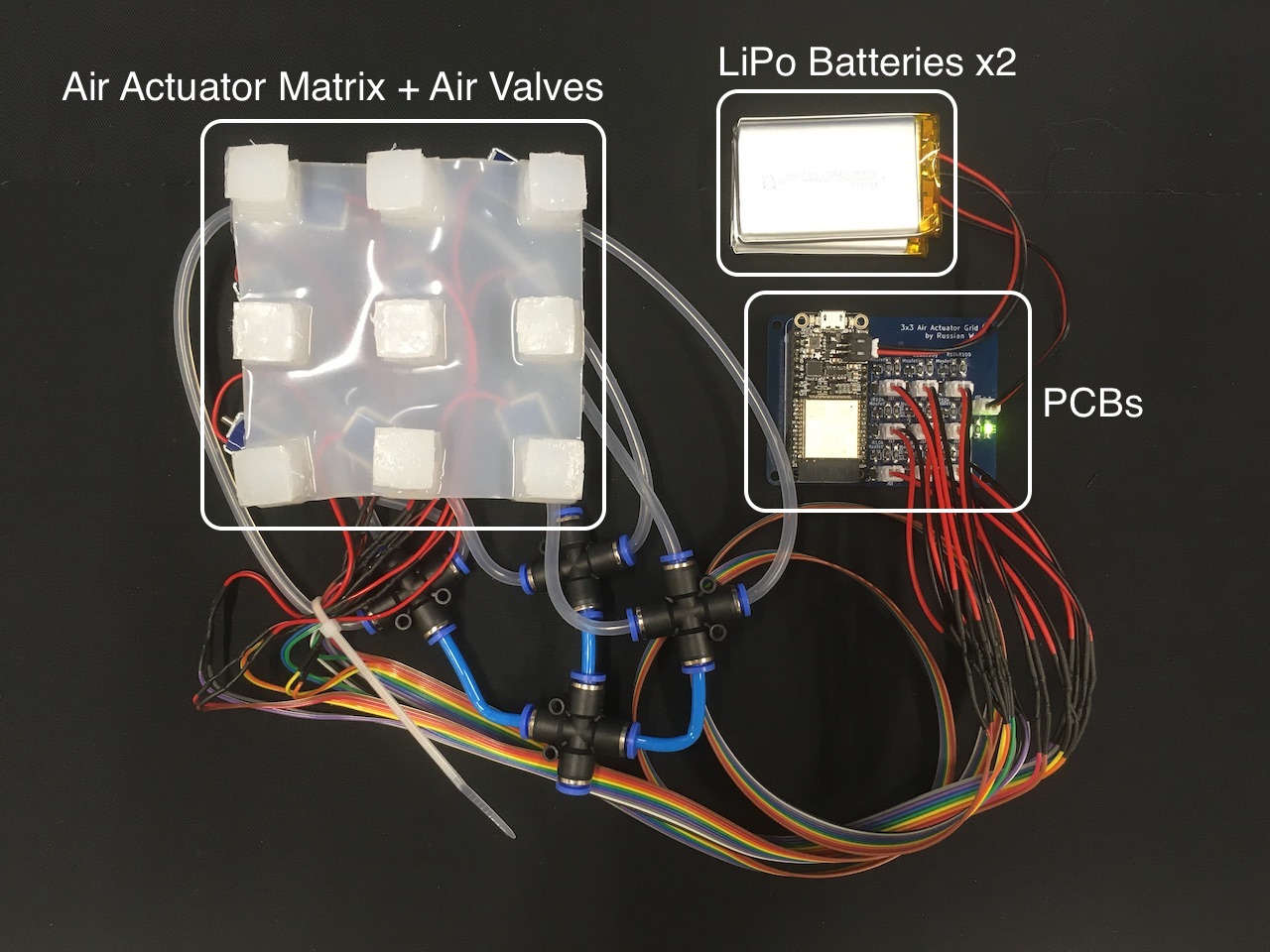

The remote hugs are realized by Air Actuator Matrix (AAM) (output) and Pressure Sensor Matrix (PSM) (input), which simulates touches and hugs to the upper body. AAM is built out of silicone and winding threads in the McKibben artificial muscle structure. By inflating and deflating it, the lengths are changed, thereby, touching or untouching the skin. PSM is built with conductive and Eeonyx fabric. By pressing crossed points, the resistances are changed to detect touches and hugs.

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

During Covid-19 pandemic, we meet the challenges of quarantine and avoiding physical contact. People feel unpleasant and stressed when they cannot meet their loved ones for a long time. Video call enables us to see and hear them, but the sense of touch is missing. Hugging Suit attempts to digitalize and deliver the touch so that the abroad students and staff are able to touch and hug their family and partner and relief homesickness and psychological stress. Because hugging is a universal body language that crosses cultures and represents endearment.

- Does your design support sustainable production, embodying circular or regenerative design practices?

The Air Actuator Matrix (AAM) is produced by 3D printed models and casting silicone. The 3D printed models were designed as reusable production tools so that can produce AAM repeatedly. The pneumatic system includes the air tank for air supply that is refillable as batteries.

- Does your design use principles of distribution and open source?

All the design files and documentation were uploaded to the project website. (Under constructions) The development steps of Hugging Suit can be found on the website.

Images