rehub

Useful information

- Team members

- Marta Donà Matteo Silverio

- Country

- Italy

- Keywords

- #glass #muranoglass #circulareconomy #3dprinting #circulardesign #energy-saving

Short Description

rehub is a lab that aims to give a second chance to waste materials using cutting-edge processes

Detailed Description

Founders have worked besides Murano glass-master for years. During these collaborations they noticed that more than 50% of the glass manipulated in Murano becomes waste. Unfortunately, this glass cannot be recycled with normal glass because of the chemical elements used to colour it. Therefore, Murano-glass waste must be processed as “special waste”, causing a big economic and environmental issue. Murano glass waste is just an example of "formally non-recyclable waste".

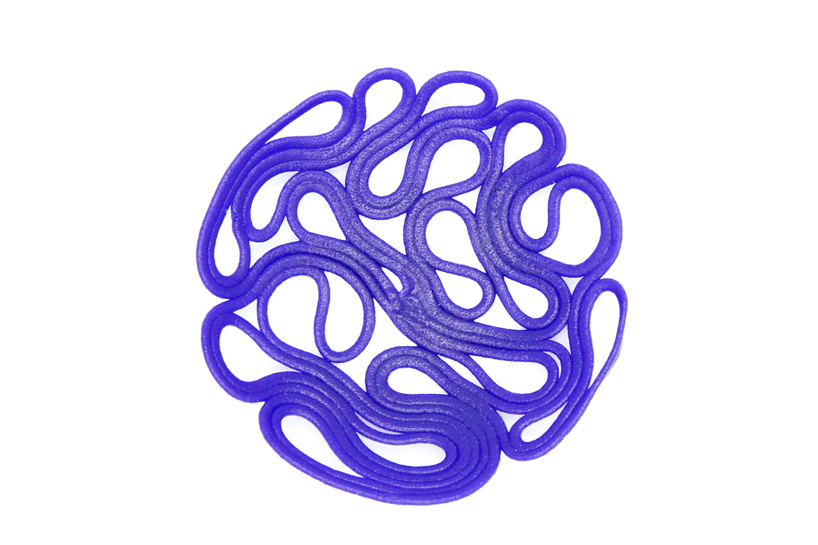

To give a solution, we managed to transform Murano glass waste in a paste that can be 3Dprinted AT ROOM TEMPERATURE using a patented extruder. Thanks to this solution we can reuse the waste locally exploiting a low-energy process and a user-friendly machine. Moreover, this solution allows glass master to realize object impossible to reproduce with traditional techniques. This process can be used with any kind of glass as well as with other non-ferrous mineral materials (like construction waste)

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

We want to first push the boundaries of a millenary tradition (Murano glass-making), demonstrating how to create a bridge between tradition and innovation by using technological advancement and a sustainable approach. We want to demonstrate how to enhance a cultural heritage without losing its essence, but fostering it using digital tools

- Does your design support sustainable production, embodying circular or regenerative design practices?

we use waste materials that usually goes to landfill.

With this project we want to enhance a better and more sustainable way of producing items, enhancing the circular economy rules. We want to mitigate the impacts of manufacturing activities reducing material explanation as well CO2 (due to transportations and material processing).

Moreover, the process we developed allow to reduce by 70% the energy need to process glass. And this process needs electricity, not glass. Therefore, all the energy needed to manipulate this waste material can be produced using sustainable resources creating an off-grid chain!IMPORTANT: to bring the glass back to its “classical” aspect (glossy and water/chemical resistant) the 3d printed object needs to be fired. However, the firing process take place at low temperature (between 600-700°) way lower than the normal temperature for glass; this process can used also domestic kiln or oven. The energy needed to run this step is already counted on the energy balance mentioned above (aka, the process uses the 30% of energy usually necessary to process glass, and in this 30% is included the firing process).

- Does your design use principles of distribution and open source?

The machine we've developed can be sold worldwide and used not only with Murano glass but also with any kind of glass. A user in the US or in Singapore can transform an old glass chandelier or a broken goblet (both are made of non-recyclable glass) in new objects.

Very important, the machine uses the marlin protocol so it can be driven by non-expert users; moreover, it works at room temperature so it’s safe!

- Does your design promote awareness of responsible design and consumption?

the core of our project is awareness: we want to promote a better material consumption promoting a new way of reusing materials fostering the circular economy rules

Images