ATHOS Era

Useful information

- Team members

- Mar Amengual Carla Barrientos Pau Gual Dídac Llopart Romina Milesi Emili Taixés

- Country

- Spain

- Keywords

- climbing footwear 3Dprinted personalized

Short Description

Athos is the first 3D-printed climbing shoe ever.

It is made based on each user’s feet and needs.

Detailed Description

Climbing shoes are a really technical and personal type of shoes that can cause important foot injuries over the years.

We found that the shape of the climbing shoes that current brands are producing is not good enough, so we decided to design a process that allows us to create a unique climbing shoe for each user.

By using AM technology, each climbing shoe is personalized and customized considering the user’s feet shape and needs.

The Athos workflow has 4 steps:

1.Feetscan of the user.

2.Personalization and customization.

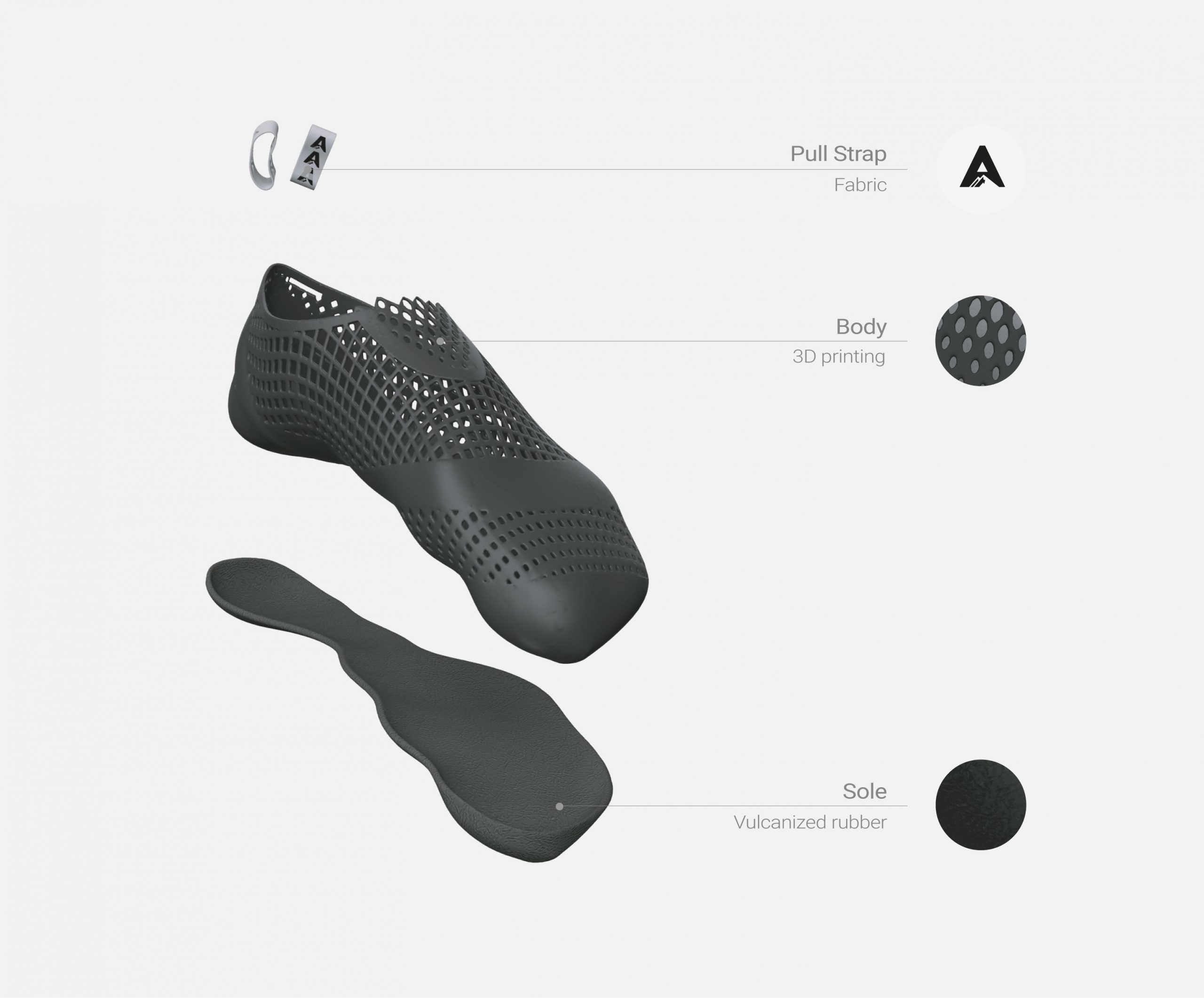

3. Printing process of the body's shoe, post-processing, and assembling parts.

4. Delivery to the user.

AM allows us to produce on a local scale in order to reduce our carbon footprint and keep the local people involved. For the manufacturing of one Athos climbing shoe you just need to print the body and assemble the rubber and the pull straps. It is a really simple manufacturing process that can be reproduced and distributed all over the world.

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

Athos wants to change the way that climbers are using and thinking about climbing shoes to turn it into a more healthy one. We really think that: “the best climbing shoe is not the one that hurts more your feet, it is the one that adapts better to your feet.”

Everybody has unique feet, everybody has unique needs. So, why don't we have unique shoes? We want to empower the user to be part of the design process and create their own and unique climbing shoes.

- Does your design support sustainable production, embodying circular or regenerative design practices?

AM allows us to produce a more sustainable product.

The current climbing shoes are a complex footwear made up of about 7 different components and materials. We are reducing it to just 3, which ends in a reduction of more than 50% in all the processes and machines involved in production.

Another important fact is that Athos is a vegan product. Nowadays, most climbing shoes are manufactured using animal skin for the body of the shoe. The body of the Athos climbing shoe is made up of TPU which is a more sustainable material that can be reused for other applications. We are studying the best way to create that regenerative design in order to give a second life to our climbing shoes.

Finally, the Athos production will be done on a local scale to reduce our carbon footprint and keep the local people involved. First, will start with the Spanish market and, then, we are going to define strategic Athos points to internationalize it.

- Does your design use principles of distribution and open source?

Using the Athos application, every user will be able to personalize their own and unique climbing shoe according to their feet shape, needs, and type of climbing.

- Does your design promote awareness of responsible design and consumption?

We are creating a unique product for each user, which ends in higher user perception and in more responsible consumption. Athos climbing shoes are not just climbing shoes. They represent much more in terms of experience and sentimental value. We want to ensure that this experience has a responsible and durable life.

Images

Video

Project Website

Social Media Accounts

Useful information

- Team members

- Mar Amengual Carla Barrientos Pau Gual Dídac Llopart Romina Milesi Emili Taixés

- Country

- Spain

- Keywords

- climbing footwear 3Dprinted personalized

Short Description

Athos is the first 3D-printed climbing shoe ever.

It is made based on each user’s feet and needs.

Detailed Description

Climbing shoes are a really technical and personal type of shoes that can cause important foot injuries over the years.

We found that the shape of the climbing shoes that current brands are producing is not good enough, so we decided to design a process that allows us to create a unique climbing shoe for each user.

By using AM technology, each climbing shoe is personalized and customized considering the user’s feet shape and needs.

The Athos workflow has 4 steps:

1.Feetscan of the user.

2.Personalization and customization.

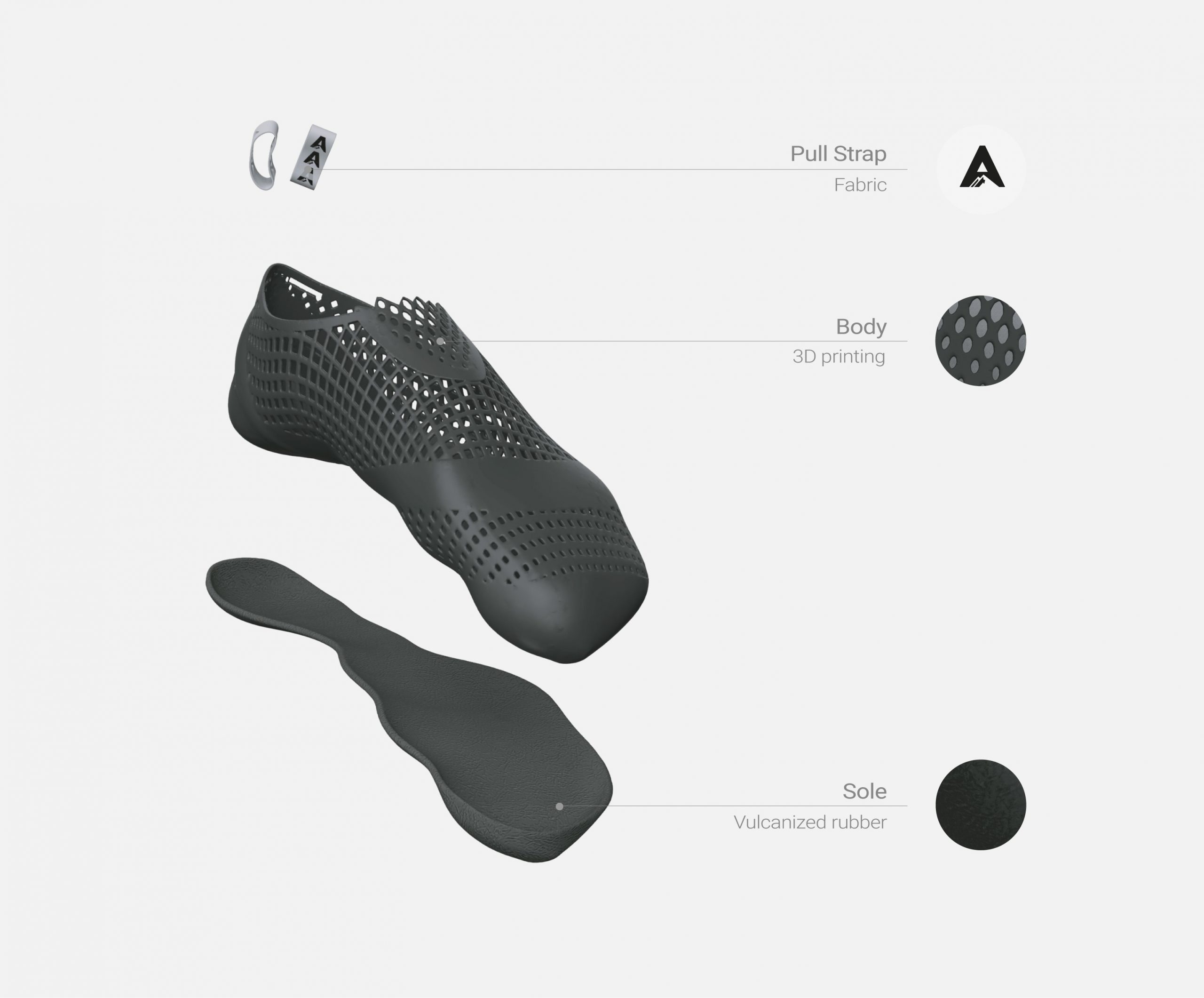

3. Printing process of the body's shoe, post-processing, and assembling parts.

4. Delivery to the user.

AM allows us to produce on a local scale in order to reduce our carbon footprint and keep the local people involved. For the manufacturing of one Athos climbing shoe you just need to print the body and assemble the rubber and the pull straps. It is a really simple manufacturing process that can be reproduced and distributed all over the world.

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

Athos wants to change the way that climbers are using and thinking about climbing shoes to turn it to a more healthy one. We really think that: “the best climbing shoe is not the one that hurts more your feet, it is the one that adapts better to your feet.”

Everybody has unique feet, everybody has unique needs. So, why don't we have unique shoes? We want to empower the user to be part of the design process and create their own and unique climbing shoes.

- Does your design support sustainable production, embodying circular or regenerative design practices?

AM allows us to produce a more sustainable product.

The current climbing shoes are complex footwear made up of about 7 different components and materials. We are reducing it to just 3, which ends in a reduction of more than 50% in all the processes and machines involved in production.

Another important fact is that Athos is a vegan product. Nowadays, most climbing shoes are manufactured using animal skin for the body of the shoe. The body of the Athos climbing shoe is made up of TPU which is a more sustainable material that can be reused for other applications. We are studying the best way to create that regenerative design in order to give a second life to our climbing shoes.

Finally, the Athos production will be done on a local scale to reduce our carbon footprint and keep the local people involved. First, will start with the Spanish market and, then, we are going to define strategic Athos points to internationalize it.

- Does your design promote awareness of responsible design and consumption?

We are creating a unique product for each user, which ends in higher user perception and in more responsible consumption. Athos climbing shoes are not just climbing shoes. They represent much more in terms of experience and sentimental value. We want to ensure that this experience has a responsible and durable life.

Images