Shoetopia - parametric shoes

Useful information

- Team members

- Barbara Motylinska Zuzanna Gronowicz

- Country

- Poland

- Keywords

- 3d-print parametric DIY footwear prosumerism distributed production sustanability

Short Description

"Shoetopia" is a distributed production system of 3d-printed sneakers.

Detailed Description

It’s a concept originally developed as a BA project.

In response to the unsustainability of the global footwear industry, we reimagine what the production and distribution of goods could look like. Why not sell perfectly fitted shoes as files, to be 3d-printed locally and personally, in just the quantity needed?

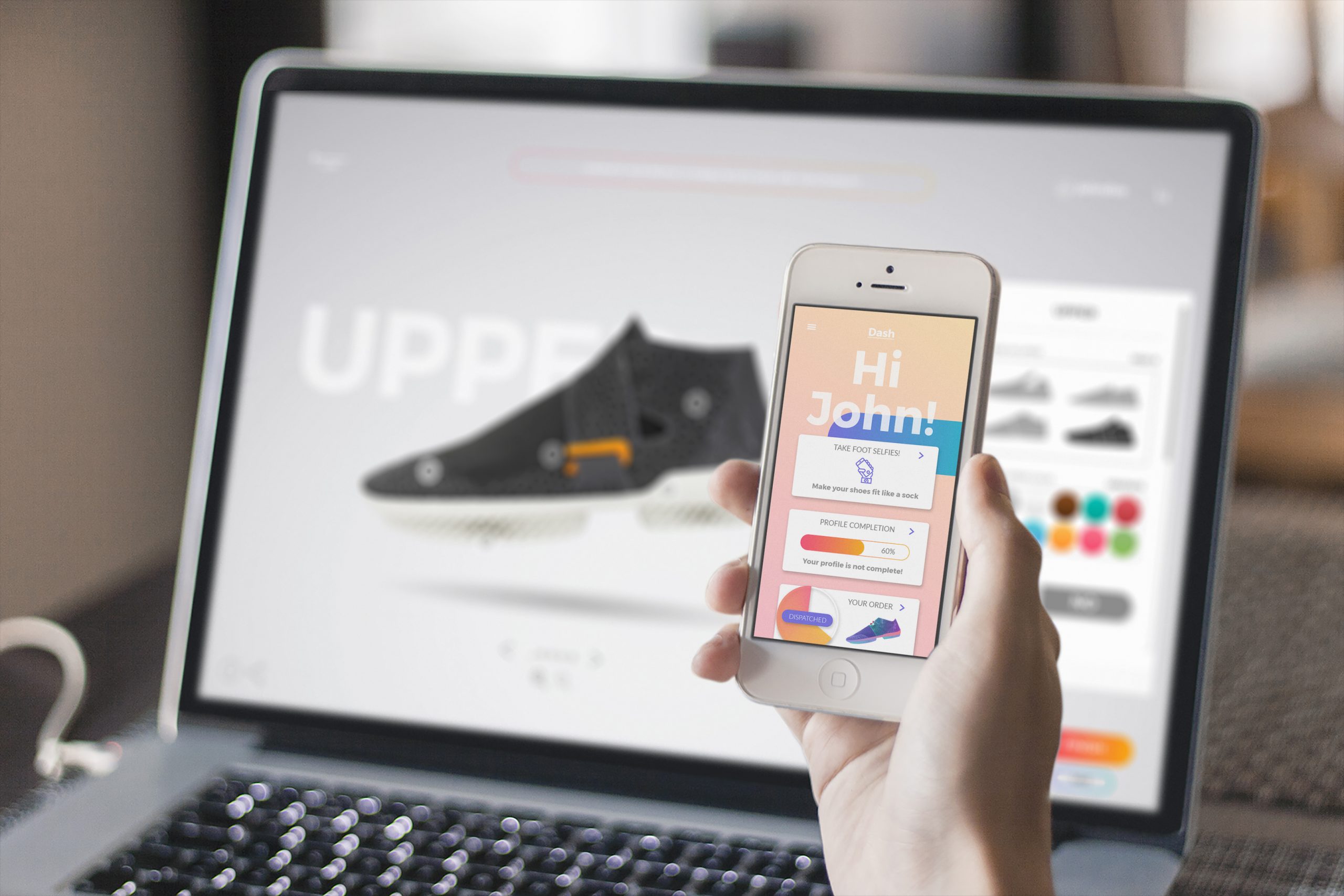

The core of the project is a fully customizable parametric sneaker model, a DIY measuring app and a web platform connecting local clients, makers and biodegradable material distributors. First, the users scan their feet for a perfect fit. Then, they can personalize the shoes’ look and print a pair at home or order production in a local maker hub. Over time, individual damaged elements can be exchanged and once the worn-out shoe is thrown out, it can decompose, thanks to material unification.

The expected impact is promoting prosumerism and alternative production systems, sustainable habits, such as repairing and reusing materials and building a maker-prosumer network.

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

The project addresses human wellbeing by enabling full customization of shape and insole, based on a personal foot scan. No 2 feet are the same and by acknowledging that in design we can help prevent many podiatric disorders! It is also expressed in our recommended material choices - by combining a 3d-printed sole and an experimental method of printing directly onto fabric for the upper shoe, we push a definition of what a 3d-printed shoe means. The sole structure is light and elastic, to provide maximum comfort. With the implementation of textile, it gains perspiration properties and the ability to absorb sweat, comparable to a commercially-produced sneaker.

- Does your design support sustainable production, embodying circular or regenerative design practices?

Our main objective is to propose a greener model for the fabrication and distribution of shoes. Shoetopia tries to achieve that by taking into account the whole product life cycle in the design process, reducing the number of production stages, places and the amount of waste. On-demand 3d-print technology allows to manufacture the shoe close to its final consumption place and reduce excess production.

Unlike commercial shoes, oftentimes consisting of dozens of different materials,

Shoetopia model is materially unified while maintaining elasticity and resilience.

If used with the recommended biodegradable filaments and textiles, it manifests good composting or recycling qualities.

It’s also worth noticing that all elements are assembled without glueing or sewing, so it’s possible to replace worn-out parts, thus promoting long-term use of the product.

- Does your design use principles of distribution and open source?

The business model is based on delivery of the measuring and customization service, while the shoes are distributed globally as licensed DIY files. It’s possible to DIY at home, as assembly doesn’t require specific skills or tools (other than an FDM 3d printer). Optionally, Shoetopia’s online platform can further connect you with a local maker hub and biodegradable filament distributors.

- Does your design promote awareness of responsible design and consumption?

Shoetopia aims to propose an alternative to fast fashion practices by promoting prosumerism as a fun and valuable variation of sustainable consumer behaviour.

On the one hand, the online platform highlights the carbon footprint and excess production in the global footwear industry. On the other, it promotes repairing and long-term use by building a personal relation to the product through a DIY approach.

Images