Personal Patient Pack

Useful information

- Team members

- Hannah Grogan Máire Kane

- Country

- Ireland

- Keywords

- Healthcare Emergency Care Sustainability Circular Economy Circular Design Design Innovation Closed Loop System Reimagining Healthcare

Short Description

The PPP allows single use devices to travel with the patient, reducing waste by 67% per patient.

Detailed Description

Our research stemmed from a conversation with a paramedic based in Ireland who commented: “All single use devices are thrown out. What if they could follow the patient?.”

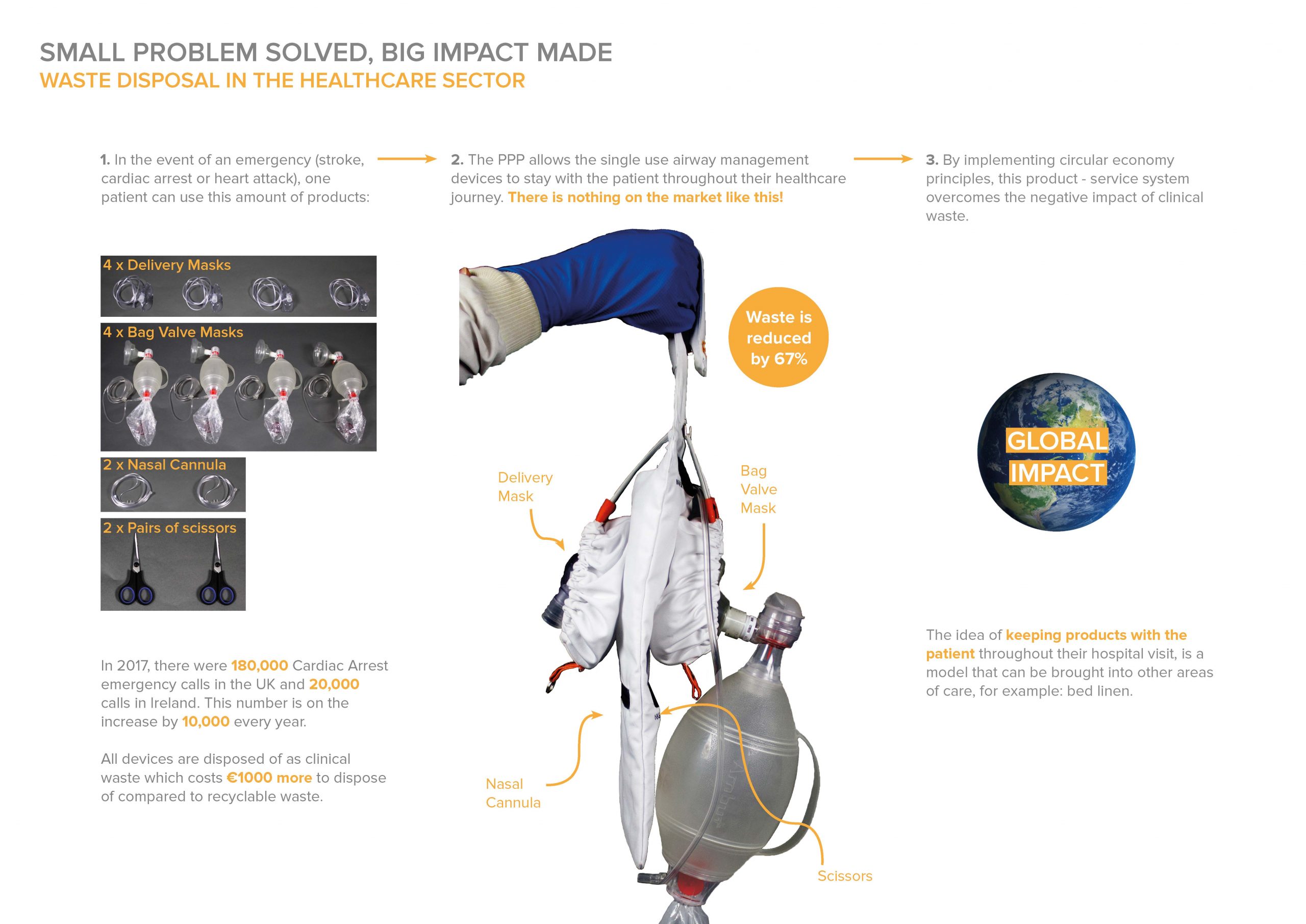

Today in the event of emergency (such as stroke, cardiac arrest or heart attack), a single patient can use up to 4 delivery masks, 4 bag valve masks, 2 nasal cannulas and 2 pairs of scissors. All of these devices are placed in the clinical waste bin immediately after use, requiring €1000 more to dispose of compared to recyclable waste. Equipped with RFID technology, the pack stays connected to the patient and allows for traceability at all times. At the end of its use, all of the pack components can be easily disassembled and recycled. The pack itself is laundered along with the existing system in place.

The head of Procurement and Infection Control in St. James' hospital in Ireland advised us to make the PPP from white polycotton fabric to ensure that dirt could be easily recognised.

Project Details

- Does your design take social and cultural challenges and human wellbeing into consideration?

The initial aim of this project was to consider and apply circular design principles to emergency medical care. Through research, it became evident that an airway management scenario produced a colossal amount of clinical waste sent for incineration. Single use devices were the main contributor to this waste.

The PPP reduces this waste by 67% by allowing devices to follow the patient. This final outcome has exceeded our initial objectives. At the moment, the Personal Patient Pack (PPP) is for airway management use. However, the idea of keeping products with the patient throughout their hospital visit, is a model that can be brought into other areas of care, regardless of age, size, ability or disability. With this being said, everyone who enters the hospital could potentially be issued their own PPP, depending on their condition.

During an interview with a senior rehabilitation nurse in Dublin, she commented: “I can see this pack being used for tracheostomy care.”

The PPP has sparked conversations of how circular economy principles can be integrated into healthcare systems. In 2019, we were invited to the Ellen MacArthur headquarters in the Isle of Wight to speak about the PPP at the DIF Festival. The Ellen MacArthur Foundation hosts regular interactive broadcasts and webinars throughout the year showcasing innovation, discussing big ideas, and sharing disruptive stories as part of our goal to inspire action and innovation towards the circular economy.

- Does your design support sustainable production, embodying circular or regenerative design practices?

Every minute of the day was entirely devoted to the PPP. From previous experience in working in medical device design firms, we are actively aware of how medical devices are most commonly designed without the vision of sustainability in mind. This has really motivated us to improve the traditional priorities in the design of medical devices.

At the beginning of our research, we interviewed a senior rehabilitation nurse in Dublin, she commented: “Saving a patient's life comes first over the sustainability of medical devices being used.” This once again influenced us to investigate this area in more depth.

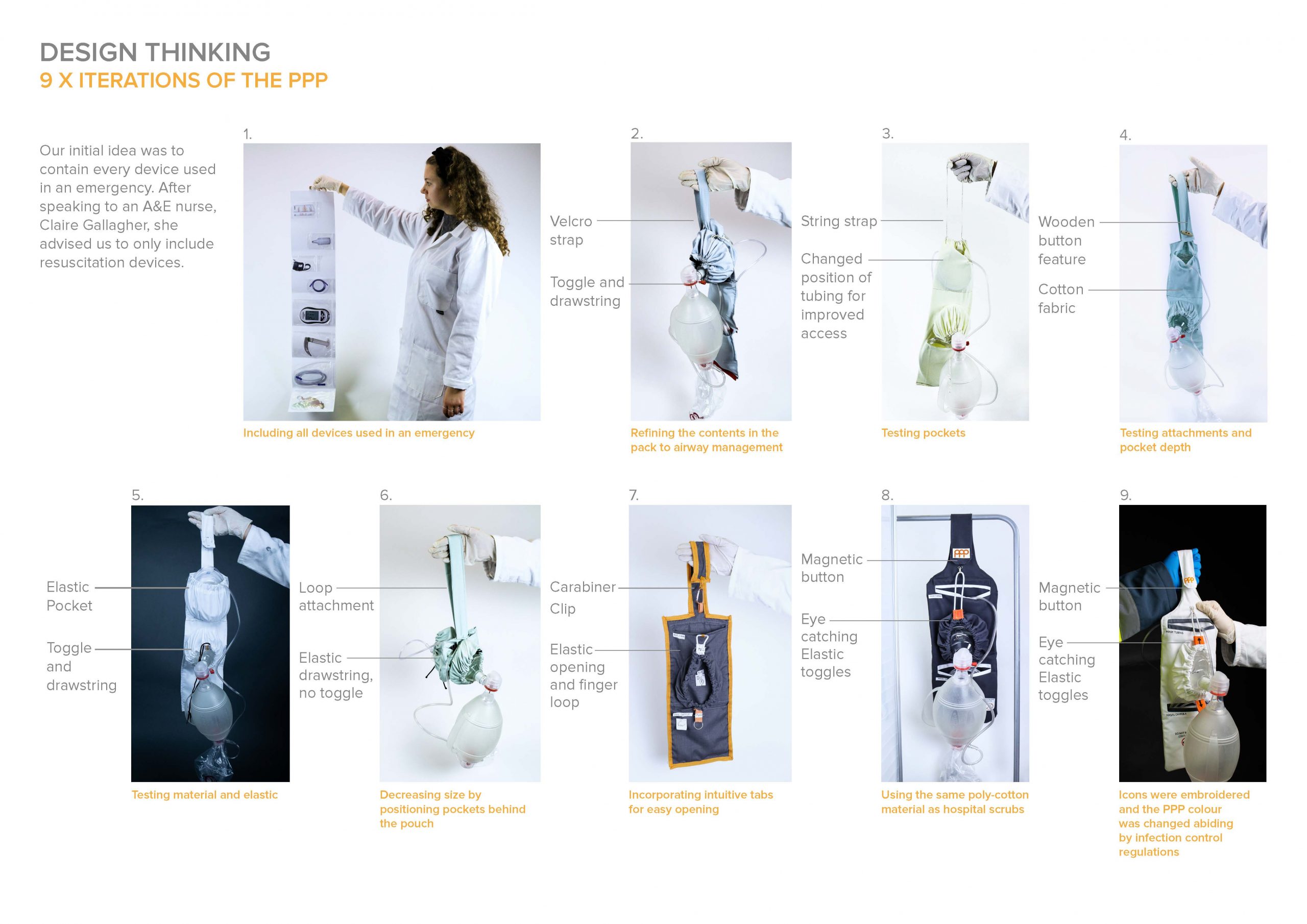

This project was a balancing act between iterative design development work in the studio alongside planning and attending interviews with healthcare professionals, researchers and experts in the field of circular economy.

By implementing circular economy principles, this product - service system reduces the negative impact of clinical waste. Through research, we realised that the sustainability of a multidimensional system could not be approached by designing a single product. We had to design a product - service system. This required an adaptation of systems already in place in the healthcare sector such as the laundry and recycling systems and the development of new ones e.g. the digital patient records.

In solving the problem of waste within healthcare, we knew that the entire system needed to be considered. The PPP is a circular product-service system. It piggybacks on existing systems already in place like the laundry facility and the current RFID platform within the hospital.

The pack is made from a polycotton material with embroidery labelling which has the potential to be laundered for over 100 cycles. No adhesives or plastic components were used in the manufacturing process, therefore at the end of the PPPs lifecycle, it can be easily disassembled and recycled.

If this system was implemented, the economic and environmental benefits could revolutionise healthcare globally for future generations.

- Does your design use principles of distribution and open source?

At the moment, the PPP is for airway management use. However, the idea of keeping products with the patient throughout their hospital visit, is a model that can be brought into other areas of care. This is only the beginning of the PPP.

The more exposure the PPP gets, the better. We want our idea to reach as many people as possible to make changes in how the healthcare systems currently operate. We want to target large-scale companies who are at the centre of the medical device design market. If awarded the Distributed Design Award, we could voice our message on a much greater platform.

As we have previously mentioned, the idea of keeping products with the patient throughout their hospital visit, is a solution that can be brought into other areas of care.

The Distributive Design Award could allow us to investigate and introduce this idea into different sections of the hospital like tracheostomy care.

- Does your design promote awareness of responsible design and consumption?

The PPP itself is designed with the user in mind. All elements have been carefully considered to ensure that anyone in the healthcare sector can immediately recognise the PPP and know exactly how to use it.

During an interview with a paramedic in Dublin, he commented:

“This PPP instantly tells me two things:

1) the patient has pre-assembled devices

2) this patient has previously had a respiratory arrest or is at risk.”This could have major benefits on patient safety. The patient is automatically recognised for needing respiratory care, which in turn would make for a more efficient patient journey.

Our design solution has the potential to help solve emergency care challenges around resource redundancy, complex supply chains and communication flows.

The circular economy thinking of the PPP offers an inspiring vision for a world that is restorative and regenerative by design. It changes the way we view resource use by aiming to eliminate the concept of waste.

These are the benefits our solution offers:

1) The hospital and ambulance services will benefit from a reduction in the volume of

clinical waste sent for incineration.

2)Products and materials are kept in use at their highest value until the end of the patient’s healthcare journey.

3) Patient records are digitalised, making for a more streamlined service.

4) Material and information flow will always be connected back to the patient.We know that sustainability is not considered with high importance in healthcare. It is our responsibility to spread the message of our project to really get healthcare bodies to start thinking differently in order to create a positive environmental change. We believe that we have used the power of creativity to do good in the world through improving the sustainability of emergency medical care. In an area that has not considered sustainability on a large scale, our product service system has the potential to reduce waste by 67% per patient.

Images